The principle of vacuum induction melting furnace is based on the process of induction heating and vacuum technology. This type of furnace is designed to melt metals in a vacuum environment, which helps to remove impurities and improve the quality of the final product.

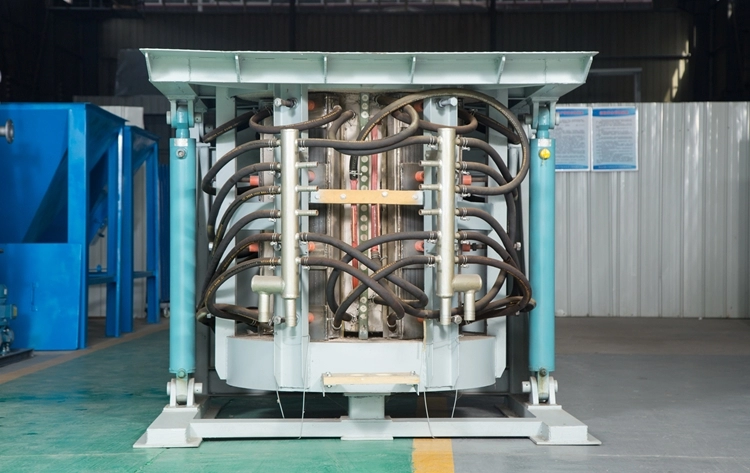

The basic principle of vacuum induction melting furnace involves three main components: the induction coil, the vacuum chamber, and the cooling system. The induction coil is responsible for generating the high-frequency electromagnetic field that heats up the metal. The vacuum chamber is where the metal is melted and maintained at a low pressure to prevent oxidation and contamination. The cooling system is used to regulate the temperature inside the furnace and prevent overheating.

When a metal is placed in the vacuum chamber, it is heated by the induction coil through a process called electromagnetic induction. This occurs when an alternating current flows through the coil, creating a magnetic field that induces an electric current in the metal. The electric current then heats up the metal, causing it to melt.

The use of a vacuum in the furnace helps to remove air and other gases that can react with the metal and cause impurities. By maintaining a low pressure inside the chamber, the risk of oxidation and contamination is reduced, resulting in a higher quality final product.

In addition to improving the purity of the metal, vacuum induction melting furnace also offers other advantages. It allows for precise control over the melting process, as the temperature can be easily adjusted by changing the frequency of the electromagnetic field. It also has a faster heating rate compared to traditional furnaces, resulting in increased productivity and efficiency.

Overall, the principle of vacuum induction melting furnace is based on the combination of induction heating and vacuum technology. It provides a controlled and efficient way to melt metals while minimizing impurities and improving the quality of the final product.