Difference between Induction Furnace vs EAF?

What is the difference between an induction furnace vs EAF? An induction furnace is a power supply device that converts 50HZ AC power frequency into medium frequency (above 300HZ to 20K HZ). It converts three-phase AC power frequency into DC power after rectification, and then converts DC power into adjustable medium frequency current to supply medium frequency alternating current flowing through the capacitor and induction coil, generate high-density magnetic field lines in the induction coil, cuts the metal materials contained in the induction coil, and generate large eddy currents in the metal materials. This eddy current also has some properties of intermediate frequency current, that is, the free electrons of the metal itself flow in the metal body with resistance to generate heat.

For example, if a metal cylinder is placed in an induction loop with alternating medium frequency current, the metal cylinder does not directly contact the induction loop, and the temperature of the energized loop itself is very low, but the cylinder surface is heated to redden, or even melted, and this reddening and melting speed can be achieved as long as the frequency and current strength are adjusted. If the cylinder is placed in the center of the coil, the temperature around the cylinder is the same, and the cylinder heating and melting do not produce harmful gas or strong light to pollute the environment.

What Is the Characteristic Difference Between Induction Furnace vs EAF?

Characteristics of Induction Furnace Series Smelting Furnace:

(1) High melting efficiency, good power saving effect, compact structure, strong overload capacity

(2) The temperature around the furnace is low, with less smoke and dust, and the working environment is good.

(3) The operation process is simple and the smelting operation is reliable.

(4) The metal composition is uniform.

(5) The melting temperature is fast, the furnace temperature is easy to control, and the production efficiency is high.

(6) The furnace has a high utilization rate and is convenient to change varieties.

(7) The long arc magnetic yoke shields the magnetic flux leakage and reduces the external magnetic resistance. The magnetic flux leakage at both ends of the shielded coil is provided. The section of the magnetic yoke is that the inner side of the arc is seamlessly attached to the outer wall, which increases the effective magnetic permeability area and makes the lower ring better supported. The unique forward and reverse coils greatly improve the efficiency of the system.

Characteristics of Induction Furnace Series Diathermic Furnace:

(1) Fast heating speed, high production efficiency, less oxidation and decarburization, saving materials and forging die costs

(2) Superior working environment, improved workers’ working environment and company image, pollution-free, low energy consumption

(3) Uniform heating, the minimum temperature difference between core and surface, high-temperature control accuracy

The heating device of medium frequency furnaces has the advantages of small size, lightweight, high efficiency, excellent hot working quality, and favorable environment, and is rapidly eliminating coal-fired furnaces, gas-fired furnaces, oil-fired furnaces, and ordinary resistance furnaces. It is a new generation of metal heating equipment.

The induction furnace is the main equipment in the casting, forging, and heat treatment workshop. Its stability, reliability, and safety are the guarantees for the normal and stable operation of the casting, forging, and heat treatment production line of the flow process.

Characteristics of EAF

EAF is an electric furnace that uses the high temperature produced by electrode arc to melt ores and metals. The energy is very concentrated when the gas discharge forms the arc, and the temperature of the arc area is above 3000 ℃. For metal smelting, the electric arc furnace is more flexible than other steelmaking furnaces, which can effectively remove sulfur, phosphorus, and other impurities. The furnace temperature is easy to control, and the equipment occupies a small area, which is suitable for smelting high-quality alloy steel.

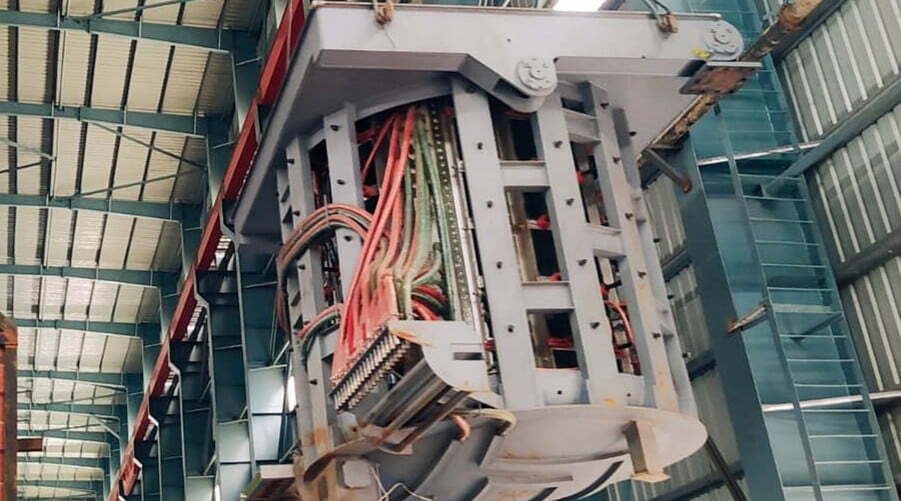

The electric arc furnace can be divided into three-phase electric arc furnaces, consumable electric arc furnaces, single-phase electric arc furnace, and resistance electric arc furnace. The furnace body of an electric arc steelmaking furnace is composed of a furnace cover, furnace door, tapping trough, and furnace stack. The furnace bottom and furnace wall are built with alkaline refractory or acid refractory. Electric arc steelmaking furnace is divided into ordinary-power electric arc furnace, high-power electric arc furnace, and ultra-high-power electric arc furnace according to the transformer capacity allocated for each ton of furnace capacity.

Electric arc furnace steelmaking is to input electric energy into the electric arc steelmaking furnace through the graphite electrode and uses the electric arc between the electrode end and the furnace charge as the heat source for steelmaking. The electric arc furnace uses electric energy as the heat source, which can adjust the atmosphere in the furnace, and is extremely favorable for smelting steel grades containing more easily oxidized elements. Not long after the invention of electric arc furnace steelmaking, it was used to smelt alloy steel and has been greatly developed.

With the improvement of electric arc furnace equipment and smelting technology, and the development of the electric power industry, the cost of electric arc furnace steelmaking continues to decline. Now, electric arc furnace steelmaking is not only used to produce alloy steel but also used to produce a large number of ordinary carbon steel. Its output is also increasing in proportion of the total steel output of major industrial countries.

In the 9th item of electric furnace steel process unit consumption in the National Maximum Quota of Nine High Power Consuming Products and Domestic Comparatively Advanced Indicators, the comparative advanced value of ordinary steel in 2005 was 500 degrees per ton, and the quota was 600 degrees per ton; The comparative advanced value of special steel in 2005 is 600 degrees/ton, and the limit is 650 degrees/ton; The advanced value of electric furnace steel for casting is 500 degrees/ton, and the limit is 700 degrees/ton.

The electric arc furnace is very expensive, but the product quality is good. The common frequency furnace costs the most electricity. The medium frequency furnace is below 2000KW, 800-900 ℃/ton, and the large furnace is 600-700 ℃/ton. These are just normal conditions. In addition to human factors (operation proficiency, equipment maintenance), equipment aging, various compensation, harmonic control, and other factors will affect the power consumption

Induction Furnace vs EAF

Compared with electric arc furnaces, induction furnace steelmaking costs less and is suitable for small and medium-sized enterprises (small workshops). However, it produces steel with many impurities and high carbon content, so the steel produced is impure. If the requirements are not high, the steel produced by medium-frequency furnaces can be selected. The electric arc furnace is large, generally, more than 3 tons, so only enterprises with a certain scale can use the electric arc furnace, and the steel it produces is relatively pure.

Electric arc furnace uses power-frequency electricity, while medium-frequency electric furnace uses medium-frequency electricity.