Ultra High Power (UHP) graphite electrodes are indispensable components in the steel manufacturing industry. Known for their reliability and cost-effectiveness, these electrodes play a crucial role in electric arc furnaces (EAFs), which are widely used for steel production. This article delves into the features, benefits, and technical specifications of UHP graphite electrodes, making them a top choice for steel manufacturers worldwide.

What are UHP Graphite Electrodes?

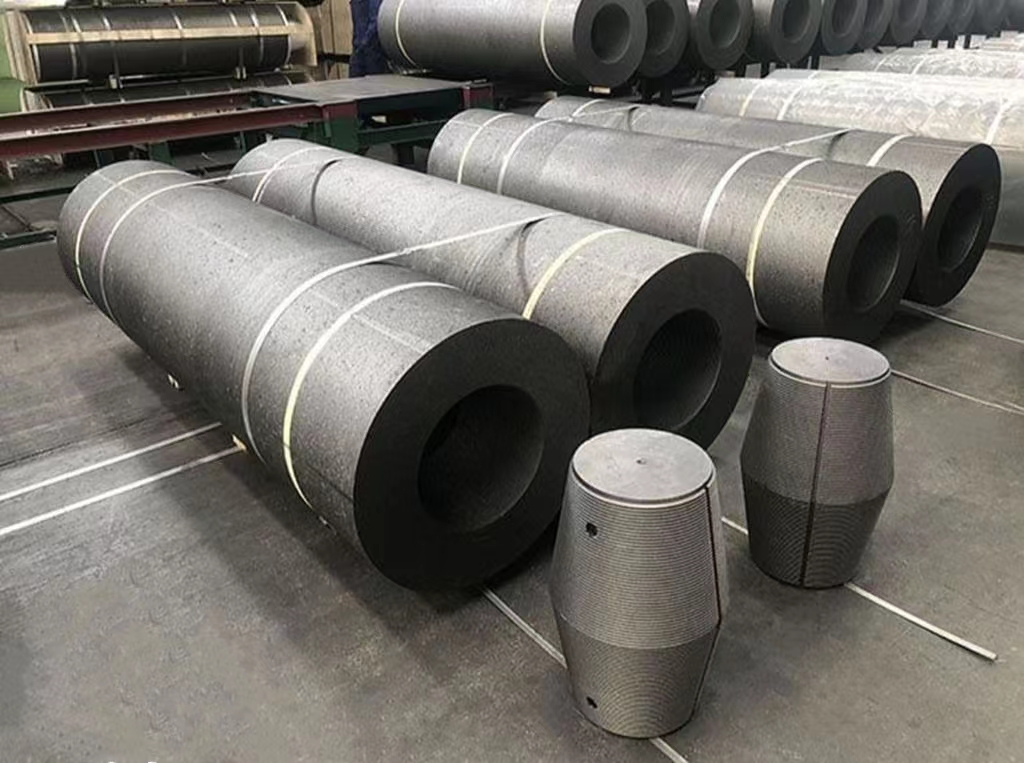

UHP graphite electrodes are high-performance electrodes designed to withstand extreme temperatures and high electrical currents. They are primarily used in EAFs for melting scrap steel and other raw materials. The term “Ultra High Power” refers to their ability to handle higher current densities compared to regular graphite electrodes, making them more efficient and durable.

Key Features of UHP Graphite Electrodes

- High Thermal Conductivity: UHP graphite electrodes exhibit excellent thermal conductivity, ensuring efficient heat transfer during the steel melting process.

- Low Electrical Resistivity: These electrodes have low electrical resistivity, which minimizes energy loss and enhances overall efficiency.

- Mechanical Strength: UHP graphite electrodes possess high mechanical strength, allowing them to withstand the physical stresses encountered in EAFs.

- Oxidation Resistance: They are resistant to oxidation, which prolongs their lifespan and reduces the need for frequent replacements.

Benefits of Using UHP Graphite Electrodes

The use of UHP graphite electrodes offers several advantages to steel manufacturers:

- Cost-Effectiveness: Due to their durability and efficiency, UHP graphite electrodes reduce operational costs over time.

- Enhanced Productivity: Their ability to handle higher current densities leads to faster melting times and increased productivity.

- Environmental Benefits: By improving energy efficiency, these electrodes contribute to lower carbon emissions and a smaller environmental footprint.

- Consistent Quality: UHP graphite electrodes ensure consistent performance, resulting in high-quality steel production.

Technical Specifications of UHP Graphite Electrodes

Below is a detailed table outlining the technical specifications of UHP graphite electrodes:

| Parameter | Value |

|---|---|

| Diameter | 300mm – 800mm |

| Length | 1200mm – 3000mm |

| Current Density | 20 – 30 A/cm² |

| Thermal Conductivity | 100 – 150 W/m·K |

| Electrical Resistivity | 5 – 8 µΩ·m |

| Flexural Strength | 10 – 15 MPa |

| Compressive Strength | 20 – 30 MPa |

| Oxidation Loss | < 1% |

| Ash Content | < 0.5% |

| Bulk Density | 1.6 – 1.8 g/cm³ |

Applications of UHP Graphite Electrodes

UHP graphite electrodes are primarily used in the following applications:

- Electric Arc Furnaces (EAFs): For melting scrap steel and producing high-quality steel.

- Ladle Furnaces: For refining and alloying steel.

- Submerged Arc Furnaces (SAFs): For producing ferroalloys and other metals.

Conclusion

UHP graphite electrodes are a vital component in modern steel manufacturing, offering unmatched reliability and cost-effectiveness. Their advanced features and technical specifications make them the preferred choice for steel manufacturers aiming to enhance productivity and reduce operational costs. By incorporating UHP graphite electrodes into their processes, manufacturers can achieve consistent, high-quality steel production while minimizing their environmental impact.

For more information on UHP graphite electrodes and other metallurgical solutions, visit HANI TECH Metallurgy.