Description

Harness advanced metallurgy with HANI’s Vacuum Arc Remelting Furnace (VAR) – engineered to produce ultra-high-purity alloys for aerospace, medical, and energy industries.

Key Highlights of HANI Vacuum Arc Remelting Furnace

-

Superior Material Quality: Achieve alloys with exceptional purity, low gas content (oxygen, hydrogen, nitrogen), and minimized inclusions.

-

Vacuum Environment: Remelt under controlled vacuum (≤0.1 Pa) to eliminate contamination and enhance microstructure uniformity.

-

Precision Control: Automated systems for stable arc stability, melt rate, and solidification parameters.

-

Wide Material Compatibility: Ideal for titanium alloys, nickel-based superalloys, zirconium, and specialty steels.

-

Customizable Solutions: Furnaces from 1 ton to 50 tons, tailored to meet specific production needs.

Technical Parameters

| Feature | Specification |

|---|---|

| Capacity | 1 ton – 50 tons |

| Vacuum Level | ≤0.1 Pa |

| Power Supply | DC/AC, 3000–15000 kW |

| Electrode Diameter | 150–800 mm |

| Cooling System | Closed-loop water cooling |

| Control System | PLC + HMI Interface |

| Warranty | 1–2 years (core components) |

| Applications | Aerospace, medical implants, nuclear, defense |

Why Choose HANI’s VAR Furnace?

-

Advanced Vacuum Technology

-

Multi-stage vacuum pumps ensure rapid evacuation and stable pressure for contamination-free melting.

-

-

Intelligent Process Control

-

Real-time monitoring of arc length, temperature, and solidification rates via PLC systems for repeatable results.

-

-

Enhanced Material Performance

-

Refined grain structure and reduced segregation improve fatigue resistance and mechanical properties.

-

-

Energy-Efficient Design

-

Optimized power distribution and water-cooled copper mold minimize energy consumption.

-

-

Modular Construction

-

Easy maintenance and upgrades with replaceable electrode arms, crucibles, and vacuum chambers.

-

-

Safety Compliance

-

Leak detection, overpressure relief, and emergency shutdown systems ensure operator safety.

-

Applications of VAR Furnace

HANI’s VAR technology is critical for industries requiring ultra-clean, high-performance alloys:

-

Aerospace: Turbine blades, engine components (Ni-based superalloys).

-

Medical: Biocompatible titanium implants, surgical tools.

-

Energy: Zirconium cladding for nuclear reactors, corrosion-resistant alloys.

-

Defense: High-strength steels for armored vehicles.

Customizable Solutions by HANI

-

Capacity Flexibility: From lab-scale 1-ton units to heavy-duty 50-ton production furnaces.

-

Retrofit & Upgrades: Modernize existing VAR systems with HANI’s advanced automation and vacuum tech.

-

Turnkey Services: Full support from design, installation, training, to after-sales maintenance.

HANI’s Global Expertise

With installations in Germany, India, Kazakhstan, and beyond, HANI Metallurgy delivers:

-

ISO-Certified Manufacturing: Quality assurance for every component.

-

24/7 Technical Support: On-site commissioning and global spare parts network.

Contact HANI Today!

Elevate your alloy production with HANI’s Vacuum Arc Remelting Furnace – where precision meets performance.

📧 Send Email | 🌐 Facebook | 📱 Twitter | 💼 LinkedIn | ▶️ YouTube

Description

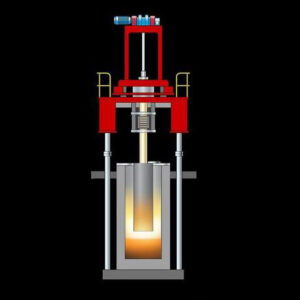

The Vacuum Arc Remelting Furnace (VAR) by HANI Metallurgy remelts consumable electrodes under vacuum or inert gas to produce metals with ultra-low impurities and superior homogeneity. Key components include:

-

Vacuum Chamber: Robust steel structure with high-pressure seals.

-

Electrode Drive System: Precision control of melting rate via servo motors.

-

Water-Cooled Crucible: Copper mold for directional solidification.

-

Analytical Ports: Sample extraction for real-time quality checks.

VAR is indispensable for critical applications where material failure is not an option.