Description

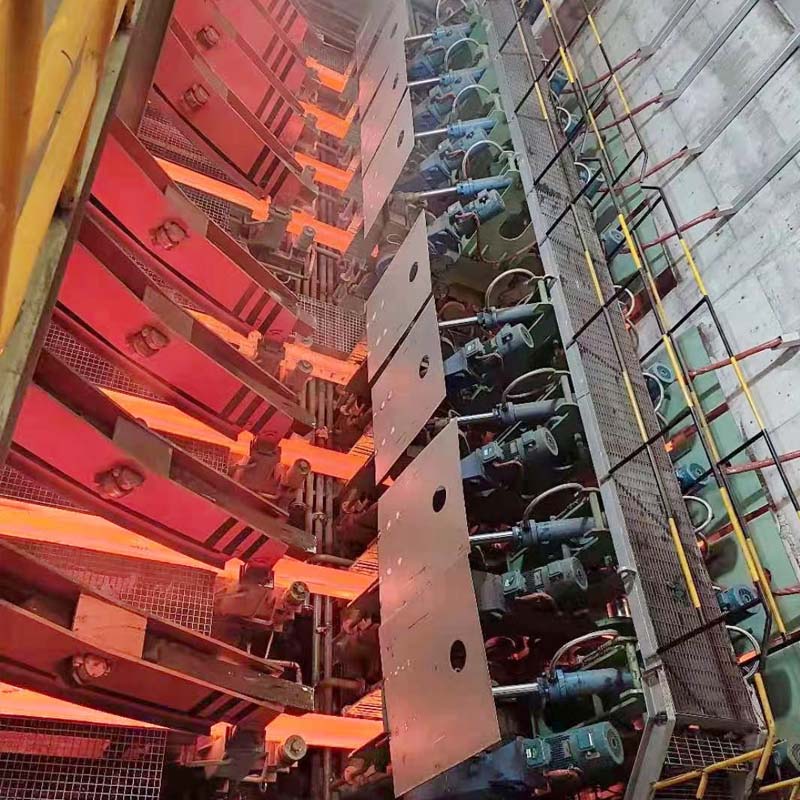

Billet Continuous Casting Machine

The workshop of the square billet continuous casting machine equiped with the automatic control system is composed of a continuous casting span and billet discharge span, which are arranged in parallel.

The rotary table of the billet continuous casting machine is arranged between the continuous casting span and the molten steel receiving span, the casting facilities, operation platform, crystallizer, vibration device, guide section equipment, dummy bar, storage equipment, cutting equipment, etc. are arranged in the continuous casting span, and the transportation roller table facilities and cooling bed facilities are arranged in the discharge span.

Tundish repair, tundish drying, tundish storage, mold maintenance, mold storage, vibration device maintenance, and other equipment are arranged in the continuous casting span plant, and the slab stacking area is set in the slab discharge span.

Square Billet Continuous Casting Machine Production Line

Annual Capacity: 1.58 million tons of qualified billets per year;

Billet Size: 150mm × 150mm, reserved 180mm × 180mm;

Cast steel: carbon structural steel, high-quality carbon structural steel, alloy structural steel, cold heading steel, electrode steel, spring steel, bearing steel, non quenched and tempered steel, steel for standard parts, etc;

Representative steel grades: Q235、82B、40Cr、ML45Mn、H08A、50CrVA、GCr15、F45MnV、BL2, etc.

The 1.58 M TPY 8-strand square billet continuous casting machine is equipped with a high-level automatic control system. It is conducive to further improving the comprehensive economic benefits

Parameter

Performance Parameters of Square Billet Continuous Casting Machine

| Serial N0. | Name | Technical Parameters |

| 1 | Caster model | Full arc |

| 2 | Number of continuous casters/set | 1 |

| 3 | Number of caster strands/strand | 8 |

| 4 | The basic radius of the mattress connecting machine / m | 10 |

| 5 | Flow quotient distance of continuous caster / m | 1200 |

| 6 | Flow casting section / mm X mm | 150×150、Reserved 180×180 |

| 7 | Fixed length / m | 12 |

| 8 | Casting speed of continuous caster / m/ min | 0.4 ~ 3.6 |

| 9 | Speed of guide rod / m / min | 5 |

| 10 | Dummy bar type | Rigid dummy bar |

| 11 | Crystallizer type | Tubular crystallizer |

| 12 | Crystallizer vibration device | Full leaf spring hydraulic vibration |

| 13 | Cutting type | Flame cutting machine |

| 14 | Blank discharge type | Double side outlet return type and hydraulic step turnover cooling bed are adopted |

Feature

Design Features of Square Billet Continuous Casting Machine Feature

(1) Large radius arc billet continuous casting machine is selected as the model of continuous caster, and continuous straightening technology is adopted to reduce the deformation rate of the continuous casting slab and prevent surface and internal cracks of the slab.

(2) Disc Ladle Turntable with lifting, weighing, and ladle capping.

(3) According to the metallurgical principle of tundish, the design is optimized, and the large capacity tundish is adopted to increase the average residence time of molten steel in the tundish and promote the full floating of inclusions.

(4) The liquid steel level of the tundish is protected by double slag: the first layer adopts synthetic slag to isolate the liquid steel from the air and absorb floating inclusions; The second layer adopts natural slag (carbonized rice husk) to cover the synthetic slag for thermal insulation.

(5) The tundish is made of alkaline refractory, whose oxide is easy to be dissolved by liquid steel and is not easy to be reduced. It has good resistance to thermal shock and mechanical corrosion of molten steel, can be fully preheated, and reduce the temperature drop of the first ladle of molten steel.

(6) The rapid replacement device of sizing nozzle of tundish can improve the number of continuous casting furnaces of continuous caster and the yield of molten steel, reduce the consumption of refractory materials, reduce the production cost and improve the economic index.

(7) When pouring high-quality steel, the ladle to tundish is protected by the long nozzle, and the tundish to crystallizer is protected by the immersion nozzle, so as to prevent the secondary oxidation of molten steel and the inhalation of gas, reduce the temperature drop of molten steel, reduce the inclusions formed in the pouring process, improve the cleanliness of continuous casting slab and ensure the quality of rolled products.

(8) Parabolic taper crystallizer is adopted, which has high cooling efficiency, small blank drawing resistance, and good billet quality, ensures high efficiency and uniformity of primary cooling, and prevents belly bulging square deviation, and leakage during high-speed casting.

(9) The mold water jacket adopts copper tube extrusion precision forming advanced technology, and the water gap is small and uniform. In this way, the air gap between the billet shell and the mold copper tube is small and the contact is good, so as to produce ideal heat exchange. The thickness of the outlet billet shell is uniform, it is not easy to break out during high-speed casting, and the billet quality is good.

(10) Equipped with automatic mold powder adding system.

(11) The automatic control of mold liquid level is adopted to reduce the wave momentum of molten steel liquid level.

(12) Mold electromagnetic stirring and end electromagnetic stirring are used to improve the surface quality of the slab, reduce slab porosity and component segregation, and improve equiaxed grain rate.

(13) Adopt mold hydraulic vibration technology: the mold vibration device adopts hydraulic vibration, full leaf spring guidance, and the vibration curve is sinusoidal and non-sinusoidal, meeting the requirements of vibration parameters for different sections, different steel grades, and different drawing speeds;

The non-sinusoidal vibration mode can reduce the negative slippage time as much as possible and further improve the surface quality of the slab on the premise of meeting the effective shelling of the slab;

It can realize the on-line adjustment of vibration parameters such as amplitude, vibration frequency and negative slip time, and effectively ensure the flexibility of production and the reliability of quality.

(14) The secondary cooling zone adopts automatically controlled air-water atomization cooling.

According to the factors such as steel grade, section, molten steel temperature, and billet drawing speed, the computer can automatically adjust the secondary cooling water distribution to achieve the best cooling effect, ensure uniform cooling, reduce billet thermal stress, improve billet solidification structure, overcome billet cracks and limit the occurrence of segregation, porosity, and central shrinkage defects.

(15) The five roller tension leveler is adopted, and the transmission device is pulled to the platform far away from the heat source through the universal joint shaft, which greatly reduces the impact of the harsh environment on the transmission device, thus greatly prolonging the service life of the tension leveler and reducing the failure rate of the tension leveler;

The design of the tension leveler not only cools the roller shaft and the inner ring of the bearing through the rotating joint but also has special considerations in the design of the bearing seat, which can directly cool the outer ring of the bearing so that the inner and outer rings of the bearing can be evenly cooled, ensuring the service life of the bearing;

A water-cooled heat shield is set between the roller bearing seat and the billet to reduce the radiation of the hot billet to the environment.

(16) The non-contact automatic sizing control technology is adopted to improve the sizing accuracy.

(17) The billet discharging mechanism adopts a two-way billet moving car and a hydraulic step-by-step turnover cooling bed. The step-by-step cooling bed has the function of automatic billet splitting and taking.

Customized Continuous Caster

We can design and manufacture the continuous caster according to the user’s steelmaking capacity, billet size, steel grade, and user site conditions. It can also be matched for manufacturers who already have continuous casting equipment.

Custom Range

Arc radius of casting machine: R2.5-10m

Billet species: square billet, round billet, slab, special-shaped billet

Continuous casting billet material: low carbon steel, low carbon alloy steel

Design production capacity: first-class 100,000 tons, second-class 200,000 tons, third-class 300,000 tons

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different needs

Production capacity can be adjusted according to customer requirements

Low energy consumption