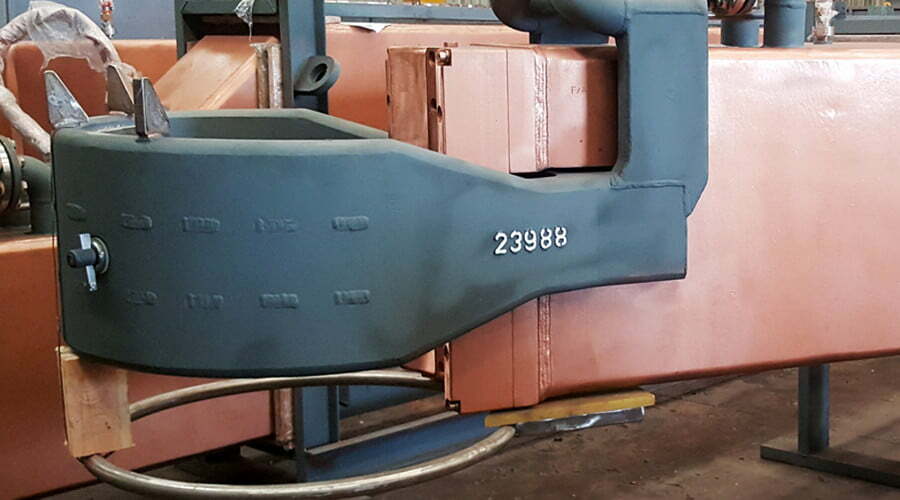

Copper Steel Composite Conductive Cross Arm

The EAF/LF Electrode Arms are widely used in steel-making electric arc furnaces, ladle refining furnaces, electro slag remelting furnaces, etc. its structure is a rectangular frame, the outer layer is a copper steel composite plate, and the outer surface of the copper plate is used to conduct electricity, and the inner part is cooled by water, so the conductive copper tube of the traditional electrode cross arm is canceled, and the conductive and supporting electrode functions of the electrode cross arm are combined into one.

After using the conductive cross arm, due to the reduction of power consumption and electrode consumption, the reduction of smelting time and hot shutdown time,

The direct economic benefits produced by each electric arc furnace every year are 1.5 million yuan for 10t furnace and more than 2.1 million yuan for 30t furnace.

The national electric furnace quality supervision and inspection center inspected the 10t electric arc furnace of the Shaanxi steel plant and the 30t electric arc furnace of the Chengdu metallurgical experimental plant with a conductive cross arm before and after the transformation. The comparison test results showed that after the transformation, the melting power consumption of 10t electric arc furnace decreased by 6.5%, and the melting rate increased by 8.9%; The melting power consumption of 30t electric arc furnace decreased by 12.7%, and the melting rate increased by 13.3%;

More than 400 sets of EAF/LF Electrode Arms produced by our company have been normal in nearly 200 metallurgical enterprises across the country.

1. Advantages of EAF/LF Electrode Arms

The lowest reactance value and resistance value.

Good insulation and cooling effect.

Convenient disassembly and maintenance.

Good rigidity and large electrode clamping force.

2. Main Technical Data of EAF Electrode Arms

| Type | Nominal capacity of electric arc furnace(t) | Rated capacity of electric furnace transformer(KVA) | Transformer constant current(KA) | Diameter of graphite electrode(mm) | Cross arm section size(mm) | Pressure of electrode release cylinder(Mpa) | Total consumption of cooling water(m3/h) |

| a×b | |||||||

| B-20 | 1.5 | 1000~1250 | 3.5 | 200 | 250×200 | 0.4 | 3 |

| BC-20 | 300×200 | 4 | |||||

| B-25 | 3 | 2200~2500 | 6.6 | 250 | 0.4 | 4 | |

| BC-25 | 360×220 | 4 | |||||

| B-30 | 5 | 2800~3200 | 8.3 | 300 | 360×210 | 0.4 | 6 |

| BC-30 | 380×240 | 4 | |||||

| B-35 | 10 | 4000~5500 | 14.0 | 350 | 420×260 | 0.4 | |

| BC-35 | 4 | ||||||

| B-35A、45B | 15 | 6300~8000 | 17.8 | 350,400 | 8 | ||

| BC-40 | 9000 | 400 | 480×360 | 5 | 4 | ||

| B-40 | 20 | 8000~10000 | 24.1 | 480×340 | 4 | 8 | |

| B-45 | 30 | 12500~15000 | 30.3 | 450 | 500×380 | 10 | |

| B-50 | 50 | 20000~31500 | 42.8 | 500 | 650×450 | 6 | 14 |

| B-55 | 75 | 40000~50000 | 54.5 | 550 | |||

| B-60 | 100 | 63000~80000 | 70.0 | 600 | 800×550 | 20 |

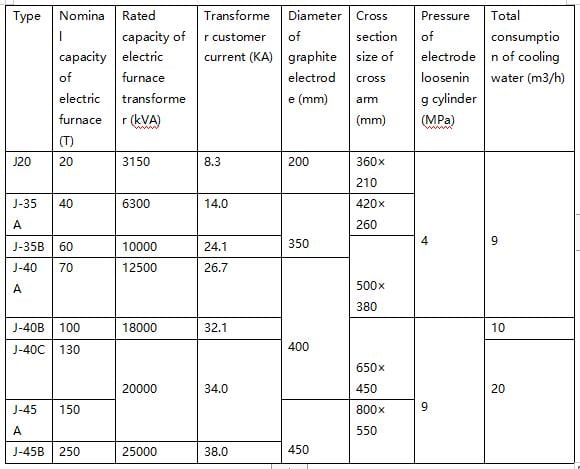

3. Technical Data of LF Electrode Arms:

Provide when ordering:

1. Geometric dimension and weight of the original cross arm

2. Maximum current at the secondary side of the transformer

3. Interface fit size