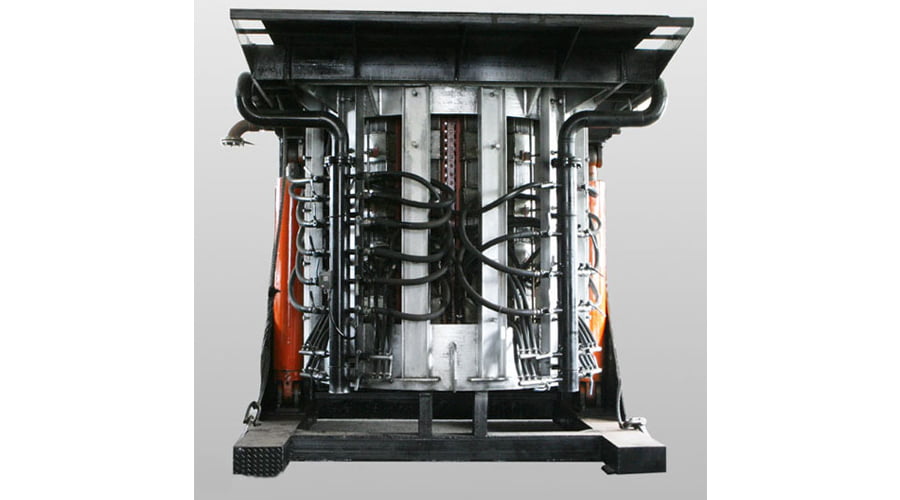

Electric induction furnace for sale, sell intermediate frequency induction furnace.

What is an induction furnace?

Induction electric furnace is the induction heating equipment with the highest heating efficiency and the fastest speed for metal materials, low consumption, energy saving and environmental protection.

Induction furnace, also known as high-frequency heating machine, high-frequency induction heating equipment, high-frequency induction heating device, high-frequency heating power supply, high-frequency power supply, high-frequency electric furnace. In addition, there are intermediate frequency induction heating equipment, ultra-high frequency induction heating equipment, etc. The range of applications is very wide.

Induction furnaces is an electric furnace, which is an industrial furnace that uses the principle of electromagnetic induction to melt metal.

There are three types of AC power used in induction furnaces: power frequency (50 Hz or 60 Hz), intermediate frequency (60-10000 Hz) and high frequency (higher than 10000 Hz).

Principle:

Electric Induction Furnace For Sale

High-frequency large current flows to a heating coil (usually made of copper tube) wound into a ring or other shape. As a result, a strong magnetic flux with instantaneous polarity changes is generated in the coil. When a heated object such as a metal is placed in the coil, the magnetic flux will penetrate the entire heated object.

In the opposite direction of the heating current inside the heated object, The corresponding large eddy current. Due to the resistance in the object to be heated, a lot of Joule heat will be generated, and the temperature of the object itself will rise rapidly, achieving the purpose of heating all metal materials.

Use:

The purpose of the electric induction furnace for sale

Heat treatment: partial or overall quenching, annealing, tempering and diathermy of various metals;

Thermoforming: whole piece forging, partial forging, hot heading, hot rolling;

Welding: brazing of various metal products, welding of various knife blades and saw blades, welding of steel pipes and copper pipes, welding of the same and different metals;

Metal smelting: (vacuum) smelting, casting molding and evaporation coating of gold, silver, copper, iron, aluminum and other metals;

Other applications of high-frequency heating machine: semiconductor single crystal growth, thermal fit, bottle mouth heat sealing, toothpaste skin heat sealing, powder coating, metal implanted plastic, etc.

Generally, the electric induction furnace produced and supplied by Hani Metallurgy is mainly used for various metal melting and heat treatment.

Classification:

The induction furnaces for sale can be divided into three categories according to the power frequency: high frequency furnaces, intermediate frequency furnaces and power frequency furnaces;

According to the purpose of the process, it can be divided into melting furnace, heating furnace, heat treatment equipment and welding equipment, etc.;

It can also be classified according to its structural form and transmission mode.

Commonly used induction furnaces are traditionally classified into cored induction melting furnaces, coreless induction melting furnaces, vacuum induction melting furnaces, induction hardening equipment and induction head heating equipment.

Hani Metallurgy hot selling all over the world is usually cored induction melting furnaces, various medium frequency induction furnaces, induction hardening equipment, etc.