Induction Furnace Circuit

The induction furnace circuit is very similar to an induction furnace transformer in the induction furnace. The induction electrothermal effect is used to complete the metal smelting process. The power supply is generally divided into three types: high frequency (above 10 kHz), intermediate frequency (50 Hz ~ 10 kHz), and power frequency (50 or 60 Hz).

According to the size and capacity of the furnace material and the frequency of the power supply, induction furnaces circuit power supply is divided into two categories: cored (mainly closed tank type) and coreless (crucible type). The induction furnace circuit is very similar to a transformer. The primary coil is an induction coil. There is an iron core in the coil of a cored induction furnace to reduce magnetic flux leakage and improve the power factor. The AC magnetic field generated by the coil induces an electromotive force in the charge, generating Joule heat.

The core induction furnace is characterized by high electric heating efficiency and high power factor, but when it starts to work, there must be a melt in the furnace, and its melting temperature is also low. It is suitable for continuous melting and heat preservation of a single variety such as non-ferrous metals and cast iron. The coreless furnace is characterized by high melting temperature and easy-to-change varieties.

The disadvantage is that the electric heating efficiency is low. It is mainly used for smelting and heat preservation of special steel, nickel-based alloys, cast iron, and non-ferrous metals.

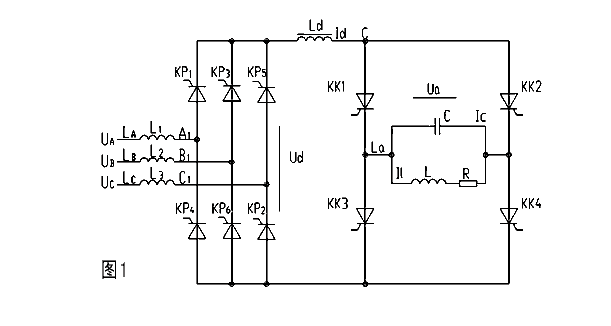

The method of heating and melting metals in ironless induction furnaces is different from electric arc furnaces, resistance furnaces, plasma furnaces, etc. It heats and melts the metal by using the induced current formed inside the metal by electromagnetic induction. In order to generate the necessary electromagnetic induction phenomenon, the basic circuit of the induction furnace is composed of a variable frequency power supply, capacitor, induction coil, and metal charge in the crucible.

Basic Principles of Induction Furnaces

The basic working principle of the ironless induction furnace is based on the principle of electromagnetic induction and the principle of the current heating effect. Simply put, due to electromagnetic induction, an induced current is generated in the metal charge, and when the induced current flows in the metal charge, heat is generated due to resistance, so that the metal charge is heated and melted.

Many characteristics of ironless induction furnace steelmaking are related to its working principle. A further understanding of the phenomenon of electromagnetic induction is very important to master this steelmaking method.

The phenomenon of electromagnetic induction and the resulting metal induction heating process is a series of complex physical processes, which include physical processes such as electricity, magnetism, and heat transfer. It is very difficult to quantitatively describe these physical processes, and now only a brief introduction is given to the relationship between electricity and magnetism, electromagnetic induction, and the relationship between electricity and heat.