Induction furnace for sale in India, intermediate frequency induction heating furnaces are induction heating equipment for metal heating such as bar, round steel, square steel, billet, steel pipe, and steel plate.

The heating temperature generally does not exceed 1250 degrees, which is suitable for pre-forging heating in the forging industry and metal quenching and tempering heating in the heat treatment industry.

Principle

Principle of induction furnace for sale in india

The relationship between the heating coil heated by the medium frequency induction heating furnace and the heated object (metal) is the same as the relationship between the primary side and the secondary side coil of the transformer. The magnetic lines of force generated by the intermediate frequency current passing through the heating coil are concentrated on the object to be heated, and the eddy current is generated by the electromagnetic induction to heat the object to be heated.

According to the type and shape of the metal, the frequency, power, heating time, holding time, coil shape, etc. of the appropriate AC current can be selected to make the metal heating meet the heating process requirements.

Features

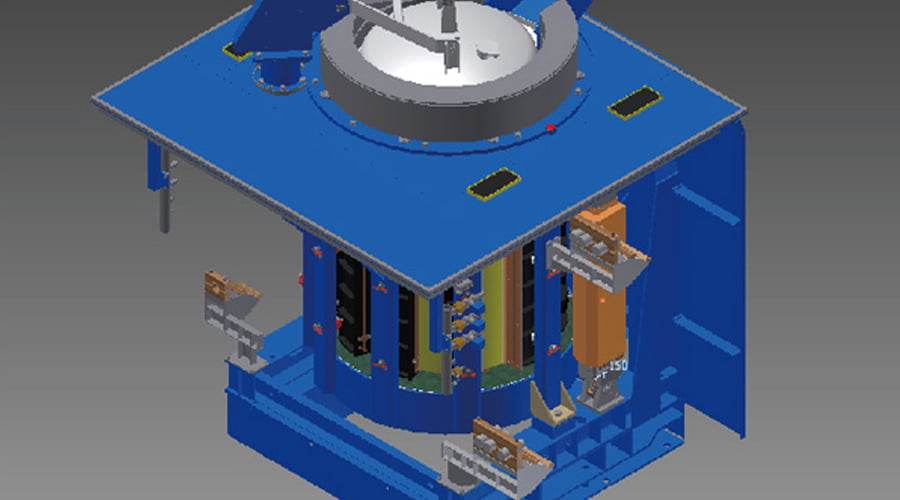

The complete equipment of intermediate frequency induction furnace consists of:

Medium frequency induction heating furnaceConsists of feeding mechanism, moving trolley, pushing mechanism, induction heating furnace, furnace cover mechanism, discharging roller table and ingot transporting trolley, operation control system, main circuit control system, furnace transformer, etc.

Induction Furnace For Sale In India Features

The intermediate frequency induction furnace has a fast heating speed and very little scale.

The intermediate frequency furnace uses the principle of electromagnetic induction, and the heat is generated by the eddy current in the workpiece itself. Very little scale, especially suitable for precision forging.

The heating sensor of the intermediate frequency induction furnace is interchangeable.

In the production process, there are many kinds of heating faults, and it is necessary to set up induction heaters of various specifications, and share a furnace rack. At this time, through the unique quick-change joints of the total upper and lower water of HANI Electric Furnace and the new tank circuit exchange mechanism developed by Hani Metallurgy, the exchange of sensors can be completed in a very short time.

The intermediate frequency induction furnace has multiple feeding and discharging structures.

Hani Metallurgy configures different feeding and discharging machines to form an optimized combination of equipment according to different process requirements of users.

The specific forms include: continuous type, batch type, etc. The discharge forms include: tilting type, straight turning type, etc.

The entire induction furnace system of Hani Metallurgy can be equipped with automatic feeding machine, discharging machine, discharging sorter, and closed-circuit water circulation system according to user requirements.

HANI’s induction furnace system has multiple protections, including water temperature and water pressure alarms in the cooling water circuit, and the temperature has upper and lower limit alarms.

The intermediate frequency furnace system of HANI electric furnace has good stability.

The continuous feeding of large bars reduces the impact on the intermediate frequency power supply.

And it is combined with the power supply to form a closed-loop temperature control to ensure that the heating temperature of the returning material is consistent from the beginning to the end, and the temperature difference between the core and the surface is small.

Induction furnace for sale in India by Hani Metallurgy are also sold all over the world.

Any needs and questions, please feel free to contact us!