Induction furnace how it works? Hani Metallurgy takes you to understand.

Induction furnace is an induction heating furnace that uses the principle of electromagnetic induction to heat metal. It is also the most widely used and widely used heating equipment in the heating industry.

It is not only used in forging industry, casting industry, hot stamping industry, but also widely used in quenching, tempering and other metal quenching and tempering of heat treatment. For induction heating to take place, two basic conditions must be met:

1.Use alternating current;

2.The object to be heated must be a metal material.

In an induction furnace, the power transmitted to the metal charge is proportional to the resistivity of the metal charge, and the heating effect of high resistivity metal materials (cast iron, steel, etc.) is better than that of low resistivity metal materials (such as copper, aluminum); ferromagnetic materials It has a better heating effect than non-ferromagnetic materials. During the heating process, the power obtained by the charge will also change due to the change of resistivity and permeability.

The resistivity of general metal materials increases with the increase of temperature, the permeability of non-ferromagnetic materials has nothing to do with temperature, and the permeability of magnetic materials has little relationship with temperature before the Curie point, but sharply after the Curie point. decline.

So, Induction furnace how it works?

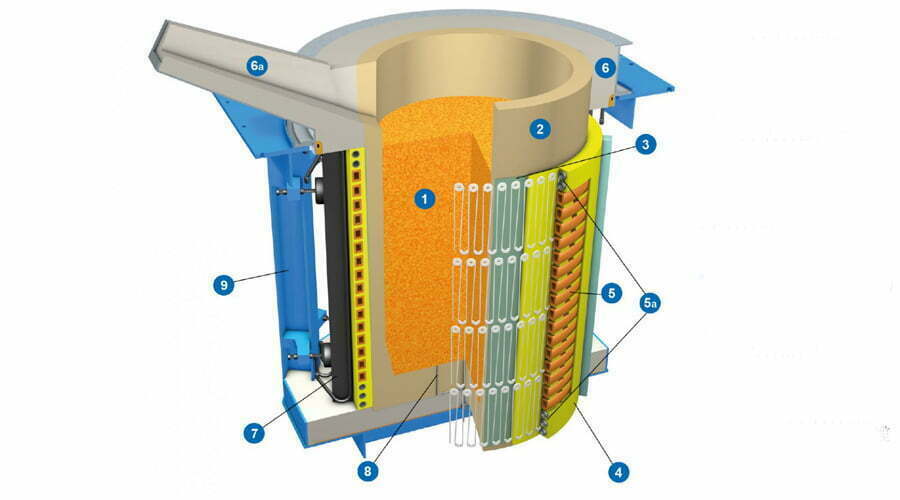

There is an induction coil in the induction furnace. When the alternating current passes through the induction coil, an alternating magnetic field is generated around the coil. The conductive material in the furnace generates an induced potential under the action of the alternating magnetic field, and a current (eddy current) is formed at a certain depth on the surface of the charge.

The metal charge to be heated is placed in an alternating magnetic field, and due to electromagnetic induction, an electric current is generated in the metal charge, and the charge is heated and melted by eddy current. Due to the resistance of the metal charge, the metal charge will be heated when the current passes through it. The induction furnace mainly uses this heat to heat and melt the metal charge.

Features

Structural features of induction furnace:

1.The central control circuit of the induction furnace optimizes the design of the combined unit circuit board, the equipment has stable performance, reliable quality and strong anti-interference ability.

2.The component layout is coordinated and reasonable, and the maintenance is convenient. Highly integrated circuit solution, commissioning and operation of steel pipe quenching and tempering furnace is fast, simple and easy to learn.

3.On the basis of zero pressure, automatic start-up scanning is added, repeated start-up, voltage and current loops are closely tracked, the induction furnace starts and stops at any time, and there is no current impact.

4.The trigger circuit sensitive to the start signal of the frequency converter uses a signal, which further improves the start performance of the induction furnace, and the start success rate is 100%.

5.The constant power circuit control system of the induction furnace will be a high-quality automatic control device for rapid changes in charging voltage and current during production, without the need to manually adjust the cut-off angle of the inverter.

6.It has a complete protection system for overvoltage, overcurrent, voltage, water shortage, and voltage limit, which ensures the reliability and operation stability of the induction furnace.

The above is the knowledge sharing about induction furnace how it works.

Hani Metallurgy will continue to share more relevant content about the metal smelting industry, please continue to follow us.

If you have any questions or needs about induction furnaces, EAF, SAF, LF and other steel melting furnaces, please feel free to contact us.