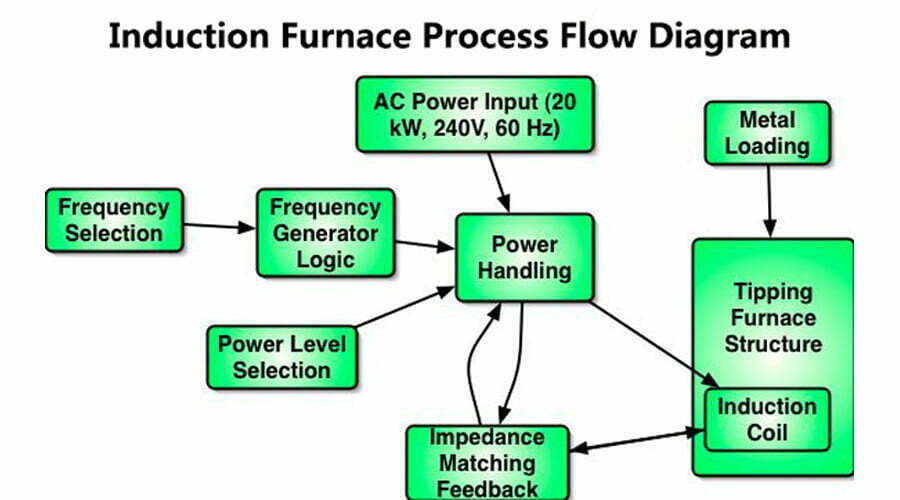

Induction furnace process flow diagram is a necessary condition for completing a professional and safe melting furnace. The complete completion of every project is inseparable from it as a design benchmark.

Induction furnace is a furnace that uses current induction to generate heat to heat and melt iron.

Induction furnaces can be divided into two types: cored and coreless. Cored induction furnaces are rarely used in steelmaking and will not be introduced here.

For coreless induction furnaces, induction furnaces can generally be divided into three types according to the frequency of the power supply:

Power frequency furnace (frequency 50 or 60Hz), directly connected to the power grid through a transformer, mainly used for smelting cast iron;

Intermediate frequency furnace (frequency 150Hz~10000Hz), the power used is intermediate frequency generator set, frequency tripler or thyristor static frequency converter:

High-frequency furnace (frequency 10KHz~300KHz), the power used is a high-frequency tube oscillator, which is mainly used for small-scale laboratory research.

The complete set of equipment of the intermediate frequency induction furnace includes: power supply and electrical control part, furnace body part, transmission device and water cooling system

All kinds of induction furnaces, whether they are core induction furnaces or coreless induction furnaces, regardless of power frequency, intermediate frequency, or high frequency, their basic circuits are composed of variable frequency power supply, capacitors, induction coils and metal furnace materials in the crucible.

Working Principle of Induction Furnace

The principle of induction heating is based on two basic laws of electricity:

One is Faraday’s law of electromagnetic induction. The magnitude of the induced electromotive force in a circuit is proportional to the rate of change of the magnetic flux passing through the circuit.

The second is the Joule-Lenz law. This law is also known as the principle of current heating effect.

Features

Features of Induction Furnace

Heating method

According to the design of the induction furnace process flow diagram, the metal charge generates eddy current under the action of the induction magnetic field, and realizes heating, melting, and refining (without direct heating) by resistance heat. The temperature is easy to control, the element volatilization and oxidation loss are small, and the alloy recovery rate is high. .

Slagging conditions

The slag is melted by the heat of molten metal. The temperature of slag is lower than that of molten steel. It belongs to cold slag, and its fluidity and reaction ability are worse than those of electric arc furnace slag.

Stirring conditions of molten metal

Rely on electromagnetic stirring to make the molten steel temperature and composition uniform, with good degassing (N2) ability.

Metallurgical function

In general, the raw material conditions are harsh and don’t have the function of removing C and P.

Smelting Process

Intermediate frequency induction furnace process

Scrap steel used in smelting usually contains a certain amount of moisture and oil. It’s not safe to directly add this kind of charge into the furnace, especially the furnace where the molten pool has been formed, and often leads to splashing. At the same time, it’s also one of the main sources of oxygen in the product.

Therefore, some factories have set up a preheating or drying system for scrap steel, and use heating to remove moisture and oil stains attached to scrap steel, so as to ensure the safety of use and prevent a source of hydrogen. In addition, adding preheated steel scrap can also shorten the melting time of smelting and reduce the consumption of electric energy.

The induction furnace process flow diagram is shown in the main figure.

The basic tasks of steelmaking: four removals and two removals, decarburization, phosphorus, sulfur, oxygen, degassing and non-metallic inclusions, alloying of alloy steel.

The induction furnace does not have the conditions for decarburization, phosphorus, and sulfur, and its raw materials must use recycled materials or metal materials that meet the conditions for decarburization, phosphorus, and sulfur. Deoxidation and alloying are carried out after melting, and the composition is adjusted by refining outside the furnace.

The use of induction melting furnaces is very common. Many companies will use induction melting furnaces when they complete heat treatment processes, hot forming and metal smelting. It is an indispensable machine for smelting companies. Therefore, the induction furnace process flow diagram has also become an indispensable calibration scheme before confirming the project.

For more knowledge about the induction furnace process, please pay attention to our website, we will continue to share relevant content.

Any questions or needs about induction furnace, electric arc furnace, ladle furnace, etc., please feel free to contact us.