Price of continuous casting machine depends on the type of machine and the number of strands, etc. Therefore, we need to know more about the continuous caster first.

What is Continuous Casting?

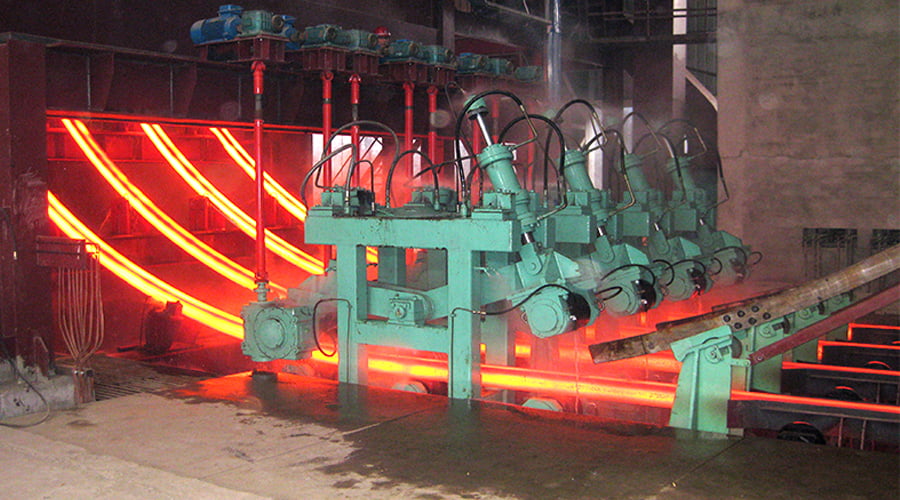

Continuous casting is the abbreviation of Continuous Steel Casting.

Continuous casting is an intermediate link connecting steelmaking and steel rolling, an indispensable part of the metallurgical process, and an important part of the steelmaking plant.

Continuous Casting:

The molten steel flows into the tundish continuously, is mixed and divided by the tundish, and then poured into the crystallizer to cool and solidify to obtain infinitely long slabs, which can be directly used for steel rolling production after cutting.

Craft

Price Of Continuous Casting Machine

Process flow of continuous casting production:

Ladle → Tundish → Crystallizer → Secondary cooling → Billet straightening → Cutting → Roller conveying → Billet transfer car (steel pusher) → Cast billet

Billet Section Dimensions

The cross-sectional size of the billet is the basis for determining the continuous casting machines. Due to the needs of finished products, the cross-sectional shape and size of the slabs are also different.

The shapes and sizes of slab continuous casting machine slabs produced so far are as follows:

Billet: 70×70 ~ 200x200mm²;

Bloom: 200×200 ~ 450x450mm²;

Rectangular Blank: 150×100 ~ 400x560mm²;

Slab: 150×600 ~ 300x2640mm²;

Round Billet: 80mm ~ 450mm.

Advantages & Features Of Continuous Caster:

1. The production process is simplified, and the demoulding, whole mold, steel ingot soaking and billet opening processes of the die casting process are omitted.

The infrastructure investment can be saved by 40%, the floor area can be reduced by 30%, the operating cost can be saved by 40%, and the consumption of refractory materials can be reduced by 15%;

2. Increase the metal yield, greatly reduce the cutting loss of billets, and increase the metal yield by about 9%;

3. Reduce the energy consumption of the production process, which can save the power consumption of the soaking furnace for billet opening, and reduce the energy consumption by 1/4 to 1/2;

4. Improve the mechanization and automation level of the production process.

To know the price of the continuous casting machine, you need to specify the machine type:

bloom continuous casting machine, vertical continuous casting machine, vertical bending continuous casting machine, straight arc continuous casting machine, full arc continuous casting machine, horizontal continuous casting machine etc., and several streams are required.

If you have any questions or needs, please feel free to contact us, we will give you the best plan and quotation as soon as possible!