Description

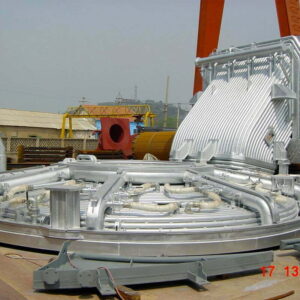

50T steelmaking electric arc furnace: The electric arc furnace body is in the shape of a teapot, which is a steelmaking reaction vessel.

The furnace body consists of a furnace body and a furnace cover (furnace top).

The outer shell of the furnace body is made of steel plate, and the inside is the furnace lining.

The furnace wall is built with magnesia brick (MgO) or chrome magnesia brick (Cr2O3, MgO).

The bottom of the furnace is in the shape of a basin, and there is a layer of magnesia burning (playing) on the clay bricks and magnesia bricks.

The acid furnace lining is built with quartz brick (SiO2) and quartz sand.

In addition to the basic requirements of strength, high temperature resistance and heat insulation, the furnace lining refractory material is also required to withstand chemical erosion of slag, thermal shock of repeated rapid changes in furnace temperature, and collision between furnace blocks and operating machinery.

Features:

Use:

This steelmaking electric arc furnace adopts alkaline lining, and can melt carbon steel, high-quality carbon steel, alloy steel, stainless steel and other varieties.

Structural Features:

50t steelmaking electric arc furnace, the structure adopts the furnace cover to remove the top charging, (EBT) or tapping nozzle, and the right or left operation is selected by the user.

Electrode lifting, furnace body tilting, furnace cover lifting and rotation are all hydraulic.

The control adopts PLC intelligent regulator control.

1. The use environment of electric arc furnace equipment

▲The altitude does not exceed 2000m;

▲Ambient temperature: within the range of 0~40°C;

▲The daily maximum and the monthly average of the humidity in the wettest month in the area of use is less than 90%;

▲There is no conductive dust, explosive gas and corrosive gas that can seriously lose metal and insulation around;

▲ Obvious vibration and bumps.

2. Smelting Cycle

|

Smelting Cycle

|

~160min ( Tapping~Tapping )

|

|

Power-on Time

|

~140min (20℃~1600℃)

Oxygen Blowing Volume 40m³/t Molten Steel

|

|

Auxiliary Time

|

20 min

|

|

Feeding (Secondary)

|

8 min

|

|

Tapping

|

3 min

|

|

Repair & Tap Packing

|

3 min

|

|

Other Auxiliary Time

|

6 min

|

Parameters

Main Parameters of 50T Steelmarking Electric Arc Furnace Equipment

|

Nominal Capacity

|

50t

|

|

Average Tapping

|

55t (6-9t steel retention)

|

|

Maximum Tapping

|

60t

|

| Inner Diameter of Furnace Shell |

5200mm

|

|

Operation Form

|

Left Operation or Right Operation

|

|

Transformer Rated Capacity

|

28MVA

|

|

Transformer Primary Voltage

|

35KV

|

|

Frequency

|

50Hz

|

|

Transformer Secondary Voltage

|

436-380-184V

|

|

436-380V

|

|

|

380-184V

|

|

|

Voltage Regulation

|

Class 19 Electric On-load Voltage Regulation

|

|

Transformer Secondary Rated Current

|

42.543KA

|

|

Transformer Cooling Form

|

Strong Oil Circulating Water Cooling

|

|

Three-phase Impedance Unbalance Factor

|

≤5%

|

|

Graphite Electrode Diameter

|

500mm (High Power Graphite Electrodes)

|

|

Electrode Distribution Circle Diameter

|

1150±50mm

|

|

Conductive Cross Arm

|

Copper-steel Composite Conductive Cross Arm, Large-section Water-cooled Cable

|

|

Electrode Rising Speed

|

6m/min(Automatic) 9m/min(Manual)

|

|

Electrode Descending Speed

|

4m/min(Automatic) 6m/min(Manual)

|

|

Electrode Lift Maximum Stroke

|

3800mm

|

|

Tilt Angle

|

Eccentric Bottom Tapping 20°, normal 12~15

|

|

Maximum Angle of Slag Discharge is 15°

|

|

|

Tapping Method

|

Eccentric Bottom

|

|

Furnace Cover Lift Height

|

500mm

|

|

Furnace Cover Rotation Angle

|

~70°

|

|

Slag Door Dimensions (W X H)

|

1100 X 900mm

|

|

Ladle

|

50t ~ 70t

|

|

Hydraulic System Working Pressure

|

12MPa

|

|

Hydraulic Medium

|

Water—Ethylene Glycol

|

|

Electrode Lift Control Method

|

Electro-hydraulic Proportional Valve (Import)

|

|

System Filtration Precision

|

<10μ (Level 4)

|

| Cooling Water Outlet Temperature |

≤55℃

|

|

Cooling Water Inlet Temperature

|

≤35℃

|

|

Cooling Water Consumption

|

~850m³/h

|

The scope of supply of complete sets of equipment is matched according to your actual requirements.

Electric Arc Furnace Application Range

HANI Metallurgy is an experienced Chinese manufacturer of electric arc furnaces.

Committed to providing high quality EAF and its auxiliary equipment/spare parts.

Available Range:

1 ton, 6 tons, 15 tons, 40 tons, 70 tons, 100 tons, 120 tons, 200 tons, 250 tons, 300 tons, 420 tons,

And various high-power / ultra-high-power electric arc furnaces according to customer requirements.

Smelting Range:

The electric arc furnace can not only smelt high-quality steel with low phosphorus, sulfur and oxygen content, but also can be alloyed with a variety of elements (including easily oxidized elements such as lead, boron, vanadium, titanium, and rare earths) to produce various high-quality steels and alloy steels.

Such as ball bearing steel, stainless acid-resistant steel, tool steel, electrical steel, heat-resistant steel, magnetic materials and special alloys.

Service:

For the melting of alloy steel, stainless steel, carbon structural steel and high-quality carbon steel, HANI Metallurgy can provide “turnkey” service of production line design, workshop layout, equipment manufacturing, installation and commissioning according to customer requirements.

It can also design, manufacture, transform and upgrade its existing smelting production equipment according to user requirements.