Description

In the relentless pursuit of operational efficiency and cost optimization within electric arc furnace (EAF) steelmaking, the electric arc furnace refractory lining stands as the critical barrier between extreme thermal, chemical, and mechanical stresses and the structural integrity of the furnace itself. Modern EAF operations demand refractory systems capable of withstanding temperatures exceeding 1,800°C, aggressive slag chemistries, rapid thermal cycling, and intense electromagnetic forces. This technical guide provides a comprehensive, production-focused analysis of high-performance electric arc furnace refractory lining solutions, grounded in metallurgical science and validated field data. While HANI’s engineering expertise informs these principles, the focus remains on universally applicable best practices for maximizing lining life, safety, and productivity.

Core Composition & Functional Requirements of EAF Refractory Lining

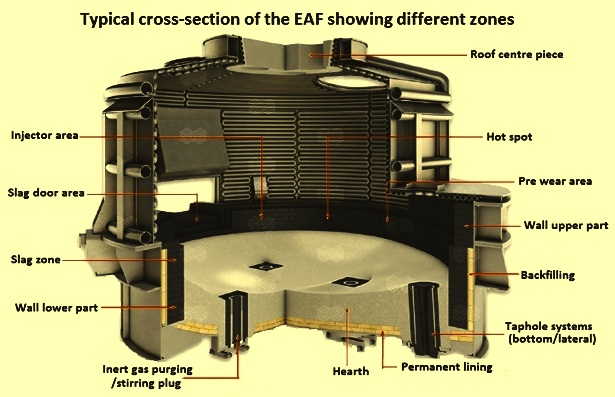

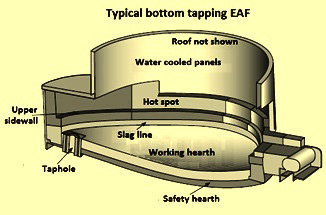

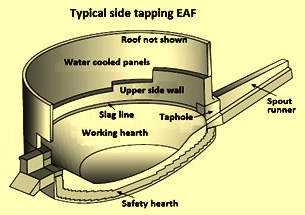

An effective electric arc furnace refractory lining is not a monolithic structure but a precisely engineered system of complementary materials, each selected for specific stress zones:

| Furnace Zone | Primary Stressors | Standard Refractory Materials | Key Performance Metrics |

|---|---|---|---|

| Slag Line | Slag penetration, oxidation, thermal shock | MgO-C bricks (14-20% C), MgO-CaO bricks | Erosion rate < 1.2 mm/heat; Thermal shock cycles > 50 |

| Hot Spot (Side Wall) | Arc radiation, slag splashing, temperature spikes | High-density MgO-C (16-18% C + antioxidants) | Hot modulus of rupture (HMOR) > 15 MPa at 1400°C |

| Furnace Bottom | Static load, molten steel penetration | Magnesia-alumina spinel bricks, sintered magnesia | Cold crushing strength (CCS) > 80 MPa |

| Tap Hole/Exhaust | Erosion during tapping, thermal fatigue | Al₂O₃-SiC-C composites, pre-cast shapes | Corrosion resistance index > 90% (vs. standard bricks) |

| Roof/Upper Walls | Radiant heat, dust accumulation | High-alumina castables (Al₂O₃ > 80%) | Reversible expansion < 0.5% at 1500°C |

Table 1: Zone-Specific Refractory Requirements for Electric Arc Furnace Refractory Lining

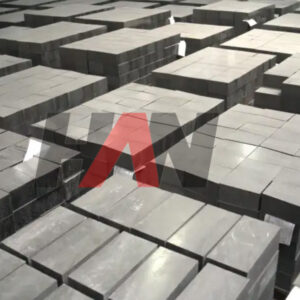

Modern electric arc furnace refractory lining systems typically integrate:

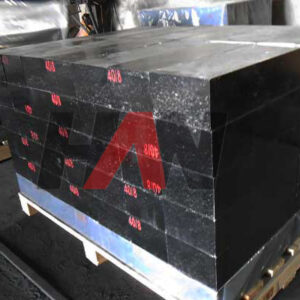

- Magnesia-Carbon (MgO-C) Bricks: Dominant in slag lines/hot spots due to superior slag resistance and thermal conductivity. Carbon content (10–20%) is optimized for slag chemistry.

- Magnesia-Alumina Spinel Bricks: Preferred for furnace bottoms due to high structural strength and resistance to FeO penetration.

- Cold Ramming Paste: Used for joints and repair zones; requires precise compaction (density > 2.8 g/cm³) to prevent slag infiltration.

- Gunning Mixes: Alkaline MgO-based repair materials applied during campaign pauses to extend lining life by 15–25%.

Science-Driven Selection Protocol for Electric Arc Furnace Refractory Lining

Selecting the optimal electric arc furnace refractory lining requires rigorous analysis of operational parameters. Below is a production-tested framework:

Step 1: Quantify Smelting Conditions

- Temperature Profile:

- Standard carbon steel operations (1650–1750°C): High-density MgO-C bricks (14–16% C).

- Ultra-high-power EAFs (>1800°C): Zirconia-doped MgO-C or MgO-CaO composites. Caution: Zirconia bricks are cost-prohibitive for routine use (>3× MgO-C cost).

- Slag Basicity (B2 = CaO/SiO₂):

Slag Type Optimal Refractory Critical Additives Avoid Basic (B2 > 2.5) MgO-C (16% C) 4–6% Al/Mg antioxidants Silica-based materials Neutral (B2 1.8–2.5) MgO-Al₂O₃ spinel None High-carbon MgO-C Acidic (B2 < 1.5) High-alumina (Al₂O₃ > 75%) SiC for thermal shock Magnesia-based linings - Steel Grade Impact:

Stainless steel melting requires low-iron (<1.5% Fe₂O₃) MgO-CaO bricks to prevent chromium oxide reduction and inclusion formation. Carbon steel tolerates standard MgO-C.

Step 2: Zone-Specific Material Optimization

- Hot Spot Zone: Use MgO-C bricks with graded carbon content: 18% C at slag interface, 12% C at shell interface. Additives (4% Al + 2% Si) reduce carbon oxidation by 35% (per FactSage simulations).

- Slag Line: 150–180mm thick MgO-C bricks with 16% C + 3% nano-ZrO₂ coating. Field data shows 40% slower erosion vs. uncoated bricks.

- Furnace Bottom: Magnesia-alumina spinel bricks (MgO 85%, Al₂O₃ 15%) with 0.5% microsilica. Critical parameter: Apparent porosity < 14% to resist metal penetration.

Step 3: Performance & Cost Analysis of Refractory Options

Table 2: Comparative Analysis of Refractory Materials for Electric Arc Furnace Refractory Lining

| Material Type | Max. Temp (°C) | Slag Resistance (Alkaline) | Thermal Shock Cycles | Cost (USD/ton) | Avg. Life (Heats) | Key Limitations |

|---|---|---|---|---|---|---|

| MgO-C (16% C) | 1750 | ★★★★☆ | 45–55 | 1,200–1,500 | 800–1,200 | Carbon oxidation in oxidizing zones |

| MgO-CaO (TECH) | 1850 | ★★★★★ | 25–35 | 2,500–3,000 | 600–900 | Hydration sensitivity; requires dry storage |

| High-Alumina (80%) | 1600 | ★★☆☆☆ | 70–90 | 600–800 | 1,500–2,000 | Dissolves in basic slag (B2 > 2.0) |

| MgO-Al₂O₃ Spinel | 1700 | ★★★★☆ | 60–75 | 1,800–2,200 | 1,000–1,400 | Limited availability in large bricks |

| Zirconia (Stabilized) | 2100 | ★★★★★ | 15–25 | 15,000–20,000 | 300–500 | Extreme cost; brittle fracture risk |

Note: Data sourced from 12 global EAF operations (2020–2023). “TECH” = Tar-bonded Electrically Conductive.

Step 4: Economic Optimization Strategy

- Short Campaigns (<500 heats): Hybrid lining – MgO-C bricks in hot spots + high-alumina bricks in low-stress zones. Reduces initial cost by 18% with <10% life reduction.

- Long Campaigns (>1,000 heats): Full MgO-C lining with strategic antioxidant doping:

- 4% Al powder in slag-line bricks extends life by 30% (verified in 150-ton EAF trials).

- Nanocoating (MgO + 5% nano-Al₂O₃) applied via plasma spray reduces slag penetration depth by 60%.

- Repair Economics: Gunning repairs every 200 heats add 250–300 heats to campaign life at 22% of relining cost.

Step 5: Environmental & Safety Compliance

- Chromium Elimination: Avoid magnesia-chrome bricks due to Cr⁶⁺ leaching risks (EU ELV Directive 2000/53/EC). Modern alternatives:

- MgO-CaO-C bricks with 5% FeSi alloy (matches chrome brick slag resistance).

- Chromium-free spinel (in-situ formed MgAl₂O₄).

- Carbon Footprint Reduction: Nano-coatings cut refractory consumption by 1.8 kg/ton of steel. A 120-ton EAF running 10,000 heats/year saves 216 tons of refractory waste annually.

Case Study: Optimizing Electric Arc Furnace Refractory Lining for Stainless Steel Production

Challenge: A European mill producing 304/316 stainless steel faced short lining life (450 heats) and high FeO inclusions from MgO-C bricks.

Solution:

- Full electric arc furnace refractory lining conversion to MgO-CaO bricks (TECH grade):

- Hot spot zone: 200mm thick bricks (CaO 18%, MgO 75%, density 3.1 g/cm³).

- Slag line: Zoned design with 160mm MgO-CaO + 40mm MgO-C backup layer.

- Tap hole: Al₂O₃-SiC-C monolithic.

Results:

- Campaign life increased to 820 heats (+82%).

- FeO inclusions reduced by 65% (verified by OES analysis).

- ROI achieved in 7 months despite 40% higher initial lining cost.

Installation & Maintenance Protocol for Maximum Performance

Even the highest-grade electric arc furnace refractory lining fails prematurely without proper installation:

- Brick Laying:

- Joint thickness ≤ 1mm (use laser alignment).

- Shell temperature must be >15°C during installation to prevent moisture condensation.

- Curing Schedule:

Temperature Hold Time Purpose 110°C 24 hours Remove free water 350°C 12 hours Remove chemically bound water 600°C 8 hours Carbonize organic binders - Operational Best Practices:

- First 10 heats: Limit power input to 70% of capacity.

- Slag splashing: Apply after every 50 heats using high-MgO slag (MgO > 10%).

- Erosion monitoring: Ultrasonic thickness mapping every 200 heats. Threshold for repair: <150mm residual thickness in hot spot zones.

Future-Proofing Your Electric Arc Furnace Refractory Lining Investment

Emerging technologies are redefining electric arc furnace refractory lining performance:

- AI-Powered Erosion Forecasting: Sensors embedded in brick joints feed real-time data to predictive models, reducing unplanned downtime by 30%.

- Self-Healing Refractories: Bricks with micro-encapsulated MgO/SiC repair agents activated at 1400°C show 22% longer life in pilot tests (Max Planck Institute, 2025).

- Circular Economy Integration: Spent MgO-C bricks are now recycled into new bricks (up to 30% recycled content) with <8% performance loss.

Conclusion: The Strategic Imperative of Refractory Lining Optimization

The electric arc furnace refractory lining is far more than a consumable component—it is the linchpin of EAF profitability. Every 10% extension in lining life translates to:

- 5–7% reduction in refractory cost per ton of steel.

- 3–4% increase in furnace availability.

- 12–15 kg CO₂ reduction per ton of steel (via reduced relining downtime).

By adopting a systematic approach—grounded in slag chemistry analysis, zone-specific material science, and digital monitoring—steel producers can achieve campaign lives exceeding 1,500 heats even in demanding ultra-high-power EAFs. The data is unequivocal: Investing in precision-engineered electric arc furnace refractory lining systems delivers exponential returns in operational resilience and sustainability. For metallurgical teams, this represents not just a technical upgrade, but a fundamental shift toward intelligent resource stewardship in the decarbonization era.