Description

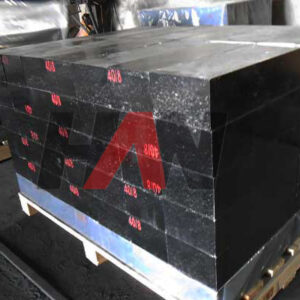

Advanced Refractory Solutions: HANI’s Alumina Magnesia Carbon Bricks

Engineered for superior performance in the most demanding high-temperature industrial environments, particularly within the steelmaking industry.

Alumina Magnesia Carbon (AMC) bricks represent a pinnacle of modern refractory engineering, meticulously designed to withstand the extreme chemical and thermal stresses found in processes like secondary steel refining. These composite bricks are not merely a mixture of materials but a sophisticated system where each component—high-purity alumina, fused magnesia, and high-grade graphite—plays a crucial role. The synergy between these elements results in a refractory lining material that offers a balanced profile of exceptional slag resistance, excellent thermal shock stability, and robust structural integrity at elevated temperatures. As industries push for greater efficiency, longer campaign lives, and cleaner steel, the demand for advanced materials like HANI’s Alumina Magnesia Carbon bricks has become paramount.

Unlike traditional refractories, AMC bricks leverage an in-situ reaction mechanism at the hot face. When exposed to the operational temperatures of a steel ladle, the alumina and magnesia components react to form a dense, stable spinel (MgAl₂O₄) layer. This self-forming protective layer acts as a formidable barrier against slag penetration and corrosion, significantly extending the service life of the refractory lining. The embedded carbon, typically in the form of high-purity flake graphite, imparts non-wettability against molten metal and slag, while its high thermal conductivity helps to dissipate thermal stress, preventing cracking and spalling. This intelligent design makes them the material of choice for critical areas such as the slag line in steel ladles.

The Science Behind Alumina Magnesia Carbon Brick Performance

The exceptional performance of Alumina Magnesia Carbon bricks is rooted in the strategic combination of its core constituents. Understanding the function of each material is key to appreciating the product’s overall value in industrial applications.

- ✔

High-Purity Fused Alumina (Al₂O₃): Serving as the structural backbone, fused alumina provides high hot strength, excellent abrasion resistance, and thermal stability. Its inherent chemical inertness contributes to the overall corrosion resistance of the brick. - ✔

Fused Magnesia (MgO): This component is the key to combating basic slags, which are prevalent in steelmaking. Magnesia’s primary role is to react with alumina at high temperatures to form the protective magnesium aluminate spinel (MgAl₂O₄) layer, which is highly resistant to slag infiltration. - ✔

High-Purity Flake Graphite (C): Graphite is a multifunctional additive. Its low coefficient of thermal expansion and high thermal conductivity grant the brick outstanding resistance to thermal shock. Furthermore, its non-wettability by molten slag and metal prevents them from adhering to and penetrating the brick surface, reducing corrosion and buildup. - ✔

Antioxidants and Binders: To protect the graphite from oxidation at high temperatures, metallic powders such as Aluminum (Al), Silicon (Si), or compounds like Silicon Carbide (SiC) are added. These elements preferentially oxidize, consuming oxygen that would otherwise burn away the carbon. Phenolic resin is typically used as a binder to provide high strength after the curing process.

Manufacturing Process: A Commitment to Quality

The production of premium Alumina Magnesia Carbon bricks is a precise, multi-stage process where quality control is integral. HANI’s manufacturing protocol ensures that every brick meets stringent performance standards, providing reliability and consistency for our clients.

- Raw Material Selection: The process begins with the rigorous selection of raw materials. We utilize high-purity fused white alumina, large-crystal fused magnesia (97% MgO or higher), and high-purity flake graphite (95% C or higher). The grain size distribution of these aggregates is carefully controlled to achieve maximum packing density.

- Precision Mixing: The selected raw materials, along with antioxidants and a thermosetting phenolic resin binder, are charged into high-intensity mixers. The mixing process is computer-controlled to ensure a perfectly homogeneous distribution of all components, which is critical for uniform properties throughout the brick.

- High-Pressure Forming: The prepared mix is then formed into bricks using high-tonnage friction or hydraulic presses. This high-pressure compaction minimizes porosity and maximizes bulk density, which directly translates to higher strength and greater resistance to slag penetration.

- Controlled Curing and Heat Treatment: After pressing, the green bricks are subjected to a carefully controlled heat treatment schedule at temperatures typically between 180°C and 300°C. This process cures the phenolic resin binder, creating a strong carbonaceous bond throughout the brick structure and developing its final mechanical properties. These bricks are sold as unburned, or “cured,” products.

- Final Inspection and Packaging: Every batch of finished bricks undergoes a comprehensive quality inspection, including dimensional checks, density measurements, and laboratory testing of key physical and chemical properties. Only bricks that pass our strict quality assurance standards are packaged for shipment.

Technical Data Sheet: Alumina Magnesia Carbon Bricks

The following table outlines the typical physical and chemical properties of our standard grades of Alumina Magnesia Carbon bricks. Custom formulations can be developed to meet specific operational requirements.

| Property | Unit | H-AMC-12 (Slag Line Grade) | H-AMC-10 (Wall/Bottom Grade) | H-AMC-08 (General Purpose) |

|---|---|---|---|---|

| Al₂O₃ | % | ≥ 65 | ≥ 60 | ≥ 55 |

| MgO | % | ≥ 10 | ≥ 8 | ≥ 6 |

| Fixed Carbon (C) | % | ≥ 12 | ≥ 10 | ≥ 8 |

| Apparent Porosity | % | ≤ 4.0 | ≤ 4.5 | ≤ 5.0 |

| Bulk Density | g/cm³ | ≥ 2.95 | ≥ 2.90 | ≥ 2.85 |

| Cold Crushing Strength | MPa | ≥ 50 | ≥ 45 | ≥ 40 |

| Modulus of Rupture (1400°C) | MPa | ≥ 10 | ≥ 8 | ≥ 7 |

| Thermal Shock Resistance (Water quench, 1100°C) |

Cycles | ≥ 20 | ≥ 15 | ≥ 12 |

Key Advantages and Performance Features

Superior Slag Corrosion Resistance

The in-situ formation of a dense, high-melting-point spinel (MgAl₂O₄) layer at the hot face creates a highly effective barrier against the penetration of molten slag. This significantly reduces the rate of chemical wear, especially in the aggressive environment of a ladle slag line.

Exceptional Thermal Shock Stability

The presence of flake graphite, with its low thermal expansion and high thermal conductivity, allows the brick to effectively manage thermal stresses caused by rapid temperature fluctuations. This minimizes the risk of cracking and structural spalling, ensuring lining integrity.

Enhanced Oxidation Resistance

Through the incorporation of specialized antioxidants, the carbon content within the brick is protected from oxidation at operating temperatures. This preserves the brick’s key properties, such as thermal conductivity and non-wettability, for a longer duration.

High Mechanical Strength

The use of high-quality raw materials and high-pressure forming techniques results in a dense, low-porosity brick structure with high cold crushing strength and hot modulus of rupture. This ensures the lining can withstand mechanical impacts and the ferrostatic pressure of molten metal.

Primary Industrial Applications

Alumina Magnesia Carbon bricks are engineered for versatility in high-temperature applications, but they truly excel in specific zones where a combination of slag resistance and thermal stability is required.

- Steel Ladle Slag Line: This is the primary application for high-grade AMC bricks. The slag line is subjected to the most severe chemical attack from corrosive slags and intense thermal cycling. The spinel-forming characteristic of AMC bricks provides the necessary protection to maximize ladle campaign life.

- Ladle Walls and Bottom: For a balanced wear profile, AMC bricks are also used in the barrel (wall) and bottom of steel ladles, often in conjunction with Magnesia Carbon bricks, to create a zoned lining that optimizes performance and cost.

- Electric Arc Furnace (EAF): Certain areas of the EAF, such as hot spots and tapping spouts, can benefit from the unique properties of Alumina Magnesia Carbon bricks.

- RH and LF Refining Furnaces: The lower vessels and snorkels of vacuum degassers are exposed to turbulent metal flow and aggressive slag, making AMC bricks a suitable material choice for extending lining life.

Frequently Asked Questions

What is the main difference between Alumina Magnesia Carbon (AMC) and Magnesia Carbon (MC) bricks?

The primary difference lies in their aggregate composition and resulting properties. Magnesia Carbon (MC) bricks use magnesia as the main aggregate and are superior in resisting highly basic slags. Alumina Magnesia Carbon (AMC) bricks use alumina as the main aggregate with added magnesia. This makes them exceptionally good at forming a protective spinel layer, offering a more balanced resistance to a wider range of slag chemistries and often providing better thermal shock resistance and structural stability compared to some MC grades.

How does the in-situ spinel formation improve the brick’s performance?

The in-situ formation of magnesium aluminate spinel (MgAl₂O₄) at the brick’s hot face is a critical performance-enhancing mechanism. This newly formed spinel layer has a very high melting point and is chemically stable. It fills the pores on the surface, creating a dense, impermeable barrier that physically blocks slag from penetrating the brick. This dramatically slows down the rate of corrosion and erosion, which is the main reason for the extended service life of AMC bricks in applications like ladle slag lines.

Are AMC bricks suitable for all types of slag?

Alumina Magnesia Carbon bricks show excellent performance against slags with a wide range of basicity (CaO/SiO₂ ratio). They are particularly effective against neutral to moderately basic slags found in many steel refining processes. For extremely high basicity slags, a high-purity Magnesia Carbon brick might be preferred. The optimal refractory choice always depends on a detailed analysis of the specific operating conditions, including slag chemistry, temperature, and holding times.

What is the typical service life of AMC bricks in a steel ladle?

The service life, or campaign life, varies significantly based on numerous factors, including the grade of steel being produced, the type of refining process (e.g., LF, RH), slag practices, ladle preheating temperatures, and the specific grade of the AMC brick used. However, when properly selected and installed, high-quality AMC bricks from a reputable supplier like HANI can significantly increase the number of heats per lining compared to conventional alumina-based refractories, often achieving over 100-150 heats in demanding slag line applications.

How should Alumina Magnesia Carbon bricks be stored?

Because AMC bricks contain a resin binder and metallic antioxidants, proper storage is crucial. They should be stored in a dry, covered environment to protect them from moisture, rain, and snow. Moisture can degrade the resin bond and oxidize the metallic additives, compromising the brick’s performance. It is recommended to keep them on pallets, off the ground, and to use them on a first-in, first-out basis, ideally within 6 months of manufacture.