Description

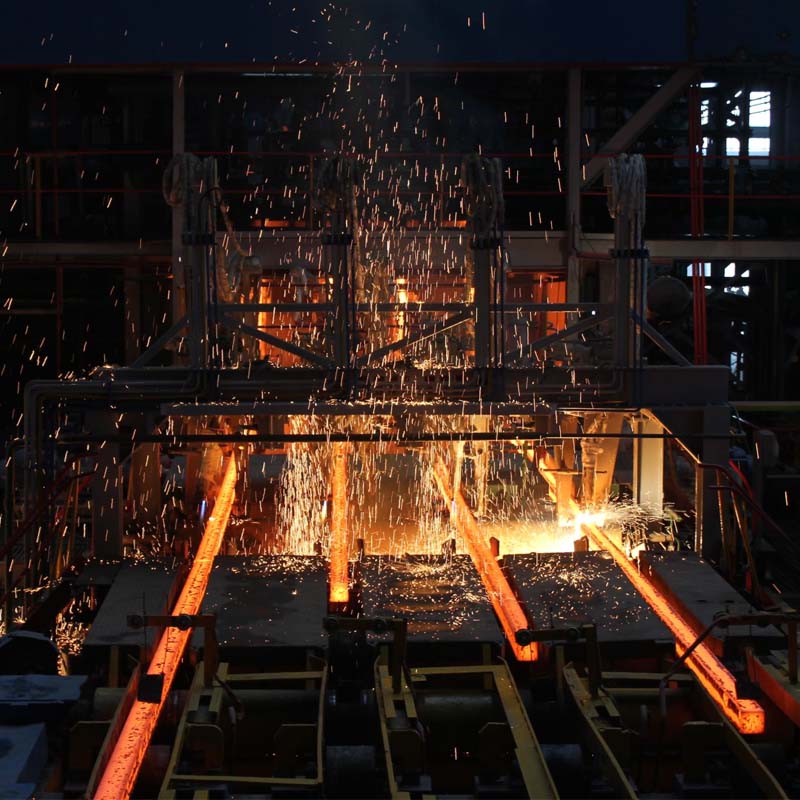

CCM Flame Cutter

Rolling Billet Flame Cutter (section steel)

The rolling billet CCM flame cutter is the main equipment on the rolling production line. Its functions mainly include two parts

(1) Cut semi-finished billet with longer length after rough rolling into short and fixed length in order to enter the finishing process;

(2) Cut the head or tail of the section steel after finishing or cut the section steel to the specified length as required.

FGT slab flame cutter designed and manufactured by Hani Metallurgy is favored by clients for its unique design, perfect function, and excellent cost-performance ratio.

The parameters of section steel that can be cut by FGT series slab fire cutter are as follows:

|

Type

|

Specifications

|

Type

|

Specifications

|

|

|

12.5#~20#Angle Steel

|

|

14/9~20/12.5Unequal angle steel

|

|

|

20#~36#Channel

|

|

16#~40#I-beam

|

|

|

100×100~H250×250

H-section steel

|

|

18U~29U

U-section steel

|

Main Features of FGT Series Slab Flame Cutter:

(1) The height of the cutting nozzle from the cutting surface can be adjusted automatically and profiles of various types and sizes can be cut.

(2) In view of the fact that the cutting thickness of cross-section of section steel varies greatly during the cutting process, two kinds of gas pressure control are adopted in the design of an energy medium system, which can regulate the gas into high pressure and low pressure and convert it automatically, thus minimizing the cutting energy consumption.

(3) The speed adjustment system of the cutting gun with AC frequency conversion can set and adjust the operating speed of the cutting gun according to the process parameters such as different specifications of the section, different steel grades, and different temperatures, so as to adjust the cutting speed to the best state.

(4) There are various body structures, such as double-column fixed cantilevers, single-column fixed cantilever,s and single-column rotary cantilevers. They can be designed and manufactured according to different conditions and demands of customers.

Intelligent CNC Flame Cutter for Hot-rolled Wide and Thick Plates

The Intelligent CNC fire cutter for hot-rolled wide and thick plates is indispensable key equipment in the hot-rolled wide and thick plate production line. Its function is to cut the super long (up to 30m) wide and thick plates after hot-rolling according to the finished products, such as scrap head cutting, scrap edge cutting, scrap end cutting, sampling cutting, and fixed-scale cutting.

ZNG hot rolling wide and thick plate intelligent CNC fire cutter designed and manufactured by Hani Metallurgy has received high praise from users for its complete functions and excellent performance. This product can replace imported equipment and is widely used in wide and thick plate production lines of major steel mills.

The main technical parameters of ZNG hot rolling wide and thick plate intelligent CNC fire cutter are as follows:

|

Subject

|

Parameter

|

|

|

Cut plate thickness (mm)

|

50 ~ 300

|

|

|

Cutting plate width( mm )

|

Single Row

|

5500

|

|

Double Row

|

3700

|

|

|

Cutting steel plate temperature(℃)

|

Room temperature~200

|

|

|

Cutter gauge( mm )

|

7600~8500

|

|

|

Flame cutter stroke( m )

|

45~60

|

|

|

CCM Flame Cutter running speed( m/min )

|

0~24.0(Servo Speed Regulation)

|

|

|

Positioning accuracy of the whole machine( mm )

|

±0.5

|

|

|

Complete machine repeatability( mm )

|

±0.3

|

|

|

Running speed of cutting gun trolley( m/min )

|

Servo Speed Regulation

|

|

|

Cutting speed of cutting gun(mm/min)

|

20~700(Servo Speed Regulation)

|

|

|

Scanning speed of steel plate contour( m/min )

|

0~24.0(Servo Speed Regulation)

|

|

|

Lifting stroke of cutting gun( mm )

|

300(automatic)

|

|

|

Automatic adjustment of high accuracy ( mm )

|

static state

|

±0.5

|

|

dynamic

|

±1.0

|

|

|

Waste Edge Cutting Travel( mm )

|

~300

|

|

|

Automatic breaking length of the waste edge( mm )

|

600~1300

|

|

|

Number of double cutting gun trolleys(set)

|

4

|

|

|

Number of Cars with Single Cutting Gun(set)

|

2

|

|

Main Features of ZNG Hot Rolling Wide and Thick Plate Intelligent CNC Flame Cutter:

1. Fast continuous scanning function. The flame cutter is equipped with a high-speed industrial camera for fast and continuous camera scanning of the contour of the cut steel plate. Compared with laser folded dot-matrix scanning, it has higher accuracy and faster speed, ensuring that the steel plate contour displayed on the display screen is exactly the same as that of the steel plate to be cut. This technology has obtained a national patent.

2. Servo speed regulation function. The cutting machine walking system and the cutting gun-walking system controlled by servo speed regulation ensure that the cutting ruler accuracy can be improved by one order of magnitude compared with that of the continuous casting slab flame cutting machine.

3. Automatic cutting function. PLC system of fire cutter has functions of automatic feed, automatic cutting, automatic sampling, automatic edge cutting, and automatic edge breaking.

4. Cutting oxygen three-stage pressure automatic switching function. When sampling automatically, the supply pressure can be adjusted automatically according to the sampling position, so that the cutting nozzle has a perforation function.

5. Temperature compensation function for plate size. When the temperature of the cut steel plate is higher than room temperature, the system will check the actual temperature of the steel plate and compensate the dimension of the steel plate to ensure the cold dimension accuracy of the hot steel plate after cutting.

6. Humanized operation function with air-conditioned fully enclosed cutting operation room on the cutting machine.

Customized Continuous Caster

We can design and manufacture the continuous caster according to the user’s steelmaking capacity, billet size, steel grade, and user site conditions. It can also be matched for manufacturers who already have continuous casting equipment.

Custom Range

Arc radius of casting machine: R2.5-10m

Billet species: square billet, round billet, slab, special-shaped billet

Continuous casting billet material: low carbon steel, low carbon alloy steel

Design production capacity: first-class 100,000 tons, second-class second-class 200,000 tons, third-class third-class 300,000 tons

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different needs

Production capacity can be adjusted according to customer requirements

Low energy consumption