Description

Elevate your metal production standards with HANI’s advanced Electroslag Remelting Furnace (ESR) – engineered to deliver ultra-clean, high-density alloys for critical applications in aerospace, energy, tooling, and defense industries.

Core Advantages of HANI’s ESR Furnace

-

Exceptional Purity: Remove sulfur, oxides, and non-metallic inclusions through controlled slag refinement.

-

Uniform Microstructure: Achieve directional solidification for minimized segregation and enhanced mechanical properties.

-

Versatile Material Compatibility: Process tool steels, superalloys, titanium, nickel-based alloys, and high-performance grades.

-

Energy Efficiency: Optimized power utilization and heat recovery systems reduce operational costs.

-

Scalable Solutions: Capacities ranging from 5 tons to 150 tons, adaptable to lab R&D or industrial-scale production.

Technical Specifications

| Parameter | Details |

|---|---|

| Furnace Capacity | 5–150 tons |

| Power Supply | AC/DC, 4000–25000 kW |

| Electrode Diameter | 150–1200 mm |

| Slag System | Customizable (e.g., CaF₂-CaO-Al₂O₃ blends) |

| Cooling Efficiency | High-pressure water-cooled copper mold |

| Control System | PLC + SCADA with real-time analytics |

| Warranty | 2 years (core components) |

| Key Applications | Turbine blades, nuclear rods, tool steels |

Why HANI’s ESR Technology Stands Out

-

Proprietary Slag Optimization

-

Tailored slag compositions maximize impurity absorption and thermal stability for specific alloys.

-

-

Intelligent Process Automation

-

Precision control of melting rate, current density, and cooling gradients via AI-driven algorithms.

-

-

Hybrid ESR/VAR Capability

-

Optional integration with vacuum systems for oxygen-sensitive materials (e.g., titanium, zirconium).

-

-

Eco-Friendly Design

-

Reduced emissions and slag waste through closed-loop recycling systems.

-

-

Robust Safety Protocols

-

Automated slag overflow prevention, arc stability monitoring, and emergency shutdown.

-

-

Modular Upgradability

-

Retrofit existing ESR units with HANI’s advanced electrode drives or IoT-enabled controls.

-

Industry Applications

-

Aerospace: Produce fatigue-resistant turbine disks and landing gear components from nickel superalloys.

-

Tooling & Die-Casting: Refine high-speed steels (HSS) and hot-work steels for extended tool lifespan.

-

Nuclear Energy: Manufacture corrosion-resistant zirconium alloys for reactor cores.

-

Defense: Create homogeneous armor steels and artillery barrels with superior impact resistance.

HANI’s Custom ESR Solutions

-

Tailored Configurations:

-

Compact ESR Units: Ideal for R&D or specialty alloy prototyping (5–20 tons).

-

Heavy-Duty Systems: High-volume production furnaces (50–150 tons) with rapid cycle times.

-

-

Retrofit & Modernization: Upgrade legacy ESR furnaces with smart controls, energy-saving components, and slag management tech.

-

End-to-End Services: From feasibility studies and furnace design to installation, training, and lifetime maintenance.

Global Support by HANI Metallurgy

With installations across Europe, Asia, and the Americas, HANI guarantees:

-

ISO 9001-Certified Manufacturing: Rigorous quality checks on critical components (electrodes, molds, power systems).

-

24/7 Technical Expertise: On-call engineers for remote diagnostics or on-site troubleshooting.

-

Spare Parts Network: Fast global delivery of consumables (slags, crucibles, sensors).

Contact HANI Now!

Optimize your alloy quality and production efficiency with HANI’s cutting-edge Electroslag Remelting Furnace.

📧 Email Us | 🌐 Facebook | 📱 Twitter | 💼 LinkedIn | ▶️ YouTube

Product Overview

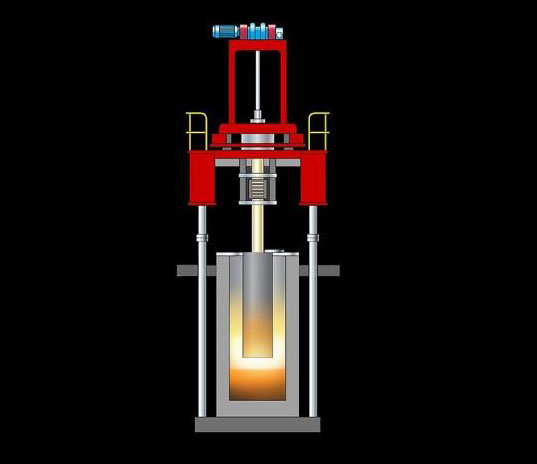

The Electroslag Remelting Furnace (ESR) by HANI employs a conductive molten slag layer to remelt metal electrodes, eliminating impurities and refining the alloy’s microstructure. Key features include:

-

Vertical Remelting Process: Ensures uniform directional solidification for defect-free ingots.

-

Adaptive Slag Chemistry: Custom slag blends for targeted impurity removal (e.g., desulfurization, deoxidation).

-

Data-Driven Analytics: IoT-enabled monitoring of temperature gradients, solidification rates, and energy use.

Ideal for industries where material consistency, fatigue resistance, and structural integrity are non-negotiable.