Description

High-performance refractory solution for extreme thermal and chemical environments in steelmaking and metallurgical applications.

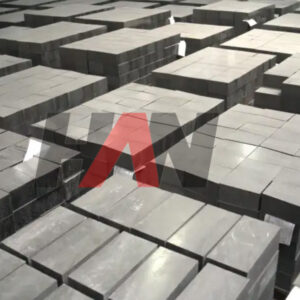

Magnesia Carbon Bricks are among the most advanced refractory materials used in modern steelmaking industries. Designed to withstand extreme temperatures, aggressive slag attack, and repeated thermal cycling, these bricks play a critical role in ensuring the longevity and efficiency of high-temperature vessels such as electric arc furnaces (EAF), basic oxygen furnaces (BOF), ladle furnaces (LF), and ladle slag lines. HANI has engineered a premium line of Magnesia Carbon Bricks that combine high-purity fused magnesia with flake graphite and optimized non-oxide additives to deliver unmatched performance under severe operating conditions.

The core composition of Magnesia Carbon Bricks revolves around magnesium oxide (MgO), which boasts a melting point of approximately 2800°C, and high-grade carbon sources—typically natural flake graphite—that resist wetting by molten slags and metals. This unique combination results in a non-fired, carbon-bonded composite refractory that maintains structural integrity at elevated temperatures while resisting chemical erosion and thermal spalling.

HANI’s manufacturing process integrates precise raw material selection, advanced mixing technology, isostatic pressing, and controlled curing to ensure consistent density, dimensional accuracy, and mechanical strength. Each batch undergoes rigorous quality checks, including chemical analysis, bulk density measurement, cold crushing strength testing, and thermal shock evaluation, to meet or exceed international standards.

Alumina Magnesia Carbon Bricks – Enhanced Slag Resistance for Ladle Applications

For ladle furnace environments where alumina-rich slags dominate, HANI offers Alumina Magnesia Carbon Bricks. These are specially formulated to balance high MgO content with significant Al₂O₃ addition, enhancing resistance to acidic and neutral slags while maintaining excellent thermal shock stability.

Tempered Magnesia Dolomite Carbon Bricks – For BOF and VOD Systems

In applications involving variable slag basicity and high FeO content—such as basic oxygen furnaces (BOF), vacuum oxygen decarburization (VOD), and GOR processes—HANI provides Tempered Magnesia Dolomite Carbon Bricks. These are engineered with a balanced ratio of MgO and CaO, derived from high-purity dolomite, to offer self-healing properties through in-situ periclase and dicalcium silicate formation.

Material Science Behind Magnesia Carbon Bricks

The performance of Magnesia Carbon Bricks is rooted in the synergistic interaction between its primary constituents. Fused magnesia (MgO) provides high refractoriness and basicity, enabling resistance to lime-saturated slags commonly found in steelmaking. Flake graphite contributes excellent thermal conductivity, reducing thermal gradients within the brick and minimizing the risk of thermal shock cracking. Additionally, carbon forms a protective layer against oxidation and slag penetration when combined with antioxidants such as metallic aluminum, silicon, or boron carbide.

HANI incorporates advanced antioxidant systems that delay the onset of carbon oxidation during idle periods or low-temperature phases. This significantly extends lining life, especially in intermittent operations like EAF campaigns. The use of phenolic resin as a binder ensures uniform distribution of carbon and facilitates strong bonding during the curing process without requiring high-temperature firing.

During service, a thin layer of slag forms on the hot face, sealing pores and further protecting the underlying refractory structure. This “self-patching” effect is crucial in maintaining the integrity of the furnace lining over multiple heats.

Manufacturing Excellence at HANI

HANI utilizes state-of-the-art production equipment to ensure consistency and reliability across all batches. The process begins with the selection of premium raw materials—high-purity fused magnesia (≥96% MgO), high-crystallinity flake graphite (≥95% C), and carefully calibrated additives. These materials are precisely weighed and mixed in high-intensity mixers to achieve homogeneity.

The mixed compound is then fed into automated hydraulic presses equipped with PLC control systems. These machines enable bi-directional pressing and isostatic compaction, resulting in bricks with uniform density and minimal internal defects. After forming, the bricks undergo a controlled drying and curing cycle at temperatures up to 250°C to polymerize the resin binder without causing thermal stress.

Every finished brick is inspected for dimensional accuracy, surface finish, and physical properties. HANI maintains an in-house laboratory capable of performing XRF analysis, cold crushing strength tests, bulk density measurements, and porosity evaluation to ensure compliance with customer specifications and international standards such as ISO 11090 and ASTM C747.

Applications Across Metallurgical Industries

- Electric Arc Furnaces (EAF): Used in the slag line and sidewall zones where exposure to high FeO slags and rapid temperature changes is common.

- Basic Oxygen Furnaces (BOF): Installed in the trunnion and slag line areas to resist highly basic slags and mechanical abrasion.

- Ladle Furnaces (LF): Applied in slag line and upper sidewall regions to combat reductive and oxidative conditions during alloying and temperature adjustment.

- Continuous Casting Ladles: Critical for protecting the slag line from prolonged contact with molten steel and secondary refining slags.

- VOD and AOD Vessels: Suitable for vacuum refining systems where low vapor pressure and high thermal cycling resistance are required.

Quality Assurance and Testing Protocols

HANI adheres to a comprehensive quality management system that covers every stage of production—from raw material sourcing to final shipment. All incoming materials are tested for chemical composition and physical properties before being approved for use. During manufacturing, process parameters such as mixing time, pressing pressure, and curing temperature are continuously monitored and recorded.

Final products undergo a battery of tests, including:

- Cold Crushing Strength (CCS) – ASTM C133

- Bulk Density and Apparent Porosity – ASTM C20

- Refractoriness Under Load (RUL) – ISO 1893

- Thermal Shock Resistance – Measured via air quenching cycles

- Chemical Analysis – X-ray Fluorescence (XRF)

HANI’s commitment to quality has enabled long-term partnerships with steel producers across Asia, the Middle East, Africa, and South America.

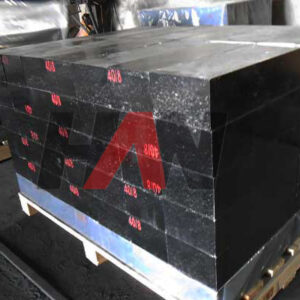

Packaging, Handling, and Storage Recommendations

To preserve the integrity of Magnesia Carbon Bricks during transport and storage, HANI packages each pallet in waterproof plastic wrap and secures it on wooden skids. For moisture-sensitive grades, paraffin dipping or wax coating is applied to prevent hydration of free MgO.

It is recommended that bricks be stored indoors in a dry, well-ventilated area, away from direct rain or humidity. Pallets should not be stacked more than two high to avoid deformation. Installation should be carried out using non-metallic trowels to prevent contamination, and joints should be minimized and properly sealed with carbon-containing mortar.

Frequently Asked Questions (FAQ)

Technical Support and Global Supply

HANI maintains a robust logistics network with partnerships across major global shipping lines, enabling timely delivery to ports worldwide. Our technical team provides on-site consultation, installation guidance, and post-installation monitoring to maximize lining performance and campaign life.

Whether you operate a small foundry or a large integrated steel plant, HANI delivers reliable, high-performance Magnesia Carbon Bricks tailored to your metallurgical needs.