Description

Unlocking Superior Performance in High-Temperature Environments with Magnesia Chrome Brick

In the relentless and demanding world of high-temperature industrial processes, the longevity and efficiency of furnace linings are paramount. The selection of refractory materials is not merely a choice but a critical investment in operational stability, product quality, and overall profitability. At the forefront of high-performance refractory solutions stands the Magnesia Chrome Brick, a material engineered to withstand the most extreme thermal, chemical, and mechanical stresses. Its unique composition, centered around magnesium oxide (MgO) and chromium trioxide (Cr2O3), forms a robust microstructure of periclase and spinel phases, granting it exceptional properties that outperform many conventional refractories.

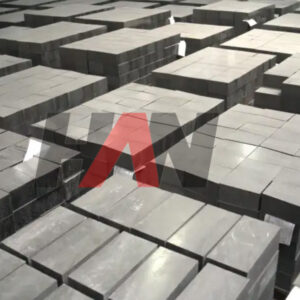

These bricks are not a one-size-fits-all solution. Their versatility and performance are derived from sophisticated manufacturing techniques that result in several distinct types, each tailored for specific, challenging applications. From the intense chemical corrosion in non-ferrous metal smelting to the severe thermal cycling in vacuum degassers, Magnesia Chrome Bricks provide a reliable barrier, ensuring process integrity and extending campaign life. This comprehensive guide delves into the science, classification, applications, and technical specifications of this essential refractory product.

The Fundamental Science Behind Magnesia Chrome Brick’s Resilience

The remarkable performance of Magnesia Chrome Brick is rooted in its mineralogical composition. The primary components, magnesia (periclase) and chrome ore, interact at high temperatures to form a composite structure with synergistic benefits:

- Periclase (MgO): This phase provides the brick with its fundamental high refractoriness and exceptional resistance to basic slags, which are prevalent in steelmaking and other metallurgical processes.

- Spinel (MgO·Cr2O3): The formation of spinel is crucial. This secondary phase forms at the boundaries of periclase grains and significantly enhances the brick’s properties. It improves thermal shock resistance by creating microcracks that absorb thermal stress, and it increases the viscosity of penetrating slag, effectively slowing down corrosion and erosion.

The type and quality of the bond between these mineral grains define the brick’s overall classification and performance level. Modern manufacturing, such as the processes perfected by HANI, focuses on creating direct bonds between crystalline phases, minimizing the weaker silicate phases that can compromise high-temperature strength and corrosion resistance.

Classification of Magnesia Chrome Bricks: Tailored for Your Application

Magnesia Chrome Bricks are broadly categorized based on their raw materials and the manufacturing process, which dictates their microstructure and, consequently, their performance characteristics. Understanding these classifications is key to selecting the optimal product for a specific industrial furnace zone.

1. Direct-Bonded Magnesia Chrome Bricks

This is a high-performance category manufactured using high-purity sintered magnesia and chrome concentrate. The key to their superior quality is the ultra-high firing temperature (typically above 1700°C). This process promotes the formation of direct bonds between periclase-periclase and periclase-spinel grains, resulting in a highly stable and robust structure with very low silicate content. They are renowned for their high-temperature strength, excellent slag resistance, and good thermal spalling resistance.

2. Semi-Rebonded Magnesia Chrome Bricks

These bricks are produced using a portion of fused magnesia-chrome clinker mixed with sintered magnesia and chrome ore. The manufacturing process involves high-pressure forming and high-temperature firing. The presence of the pre-fused material enhances the brick’s density and corrosion resistance compared to common bricks, offering a balanced performance profile. They provide improved thermal shock resistance and are a cost-effective solution for moderately severe conditions.

3. Fused-Rebonded Magnesia Chrome Bricks

Representing the pinnacle of magnesia-chrome refractory technology, these bricks are made from high-purity, pre-fused magnesia-chrome grains. These grains are produced by melting raw materials in an electric arc furnace, which results in a highly dense, low-porosity clinker with large, well-developed periclase and spinel crystals. The bricks formed from this material exhibit the highest resistance to corrosion, erosion, and slag penetration. The HANI series of fused-rebonded bricks are engineered for the most extreme service conditions where maximum furnace availability is critical.

Technical Specifications of HANI Magnesia Chrome Bricks

The following tables provide a detailed overview of the typical physical and chemical properties for different grades of our Magnesia Chrome Bricks. Please note that these values can be customized to meet specific operational requirements.

Table 1: Direct-Bonded Magnesia Chrome Bricks

| Grade | MgO (%) | Cr₂O₃ (%) | SiO₂ (%) | Bulk Density (g/cm³) | Apparent Porosity (%) | Cold Crushing Strength (MPa) | Refractoriness Under Load (T₀.₆, °C) |

|---|---|---|---|---|---|---|---|

| HMC-8D | ≥ 80 | 8 – 10 | ≤ 1.2 | ≥ 3.05 | ≤ 17 | ≥ 45 | ≥ 1700 |

| HMC-12D | ≥ 74 | 12 – 15 | ≤ 1.5 | ≥ 3.08 | ≤ 17 | ≥ 40 | ≥ 1700 |

Table 2: Fused-Rebonded Magnesia Chrome Bricks

| Grade | MgO (%) | Cr₂O₃ (%) | SiO₂ (%) | Bulk Density (g/cm³) | Apparent Porosity (%) | Cold Crushing Strength (MPa) | Thermal Shock Resistance (Cycles, 1100°C water cooling) |

|---|---|---|---|---|---|---|---|

| HMC-18F | ≥ 62 | 18 – 20 | ≤ 1.2 | ≥ 3.20 | ≤ 16 | ≥ 50 | ≥ 5 |

| HMC-25F | ≥ 55 | 25 – 28 | ≤ 1.2 | ≥ 3.30 | ≤ 15 | ≥ 55 | ≥ 6 |

| HMC-30F | ≥ 50 | ≥ 30 | ≤ 1.0 | ≥ 3.35 | ≤ 14 | ≥ 60 | ≥ 7 |

The HANI Manufacturing Advantage: From Raw Material to Final Product

Producing a superior Magnesia Chrome Brick is a science that demands precision at every stage. Our state-of-the-art manufacturing facility is built on a foundation of stringent quality control and advanced technology to ensure every brick meets the highest standards of performance and consistency.

- Rigorous Raw Material Selection: We source only the highest purity raw materials, including electro-fused magnesia, large-crystal dead-burned magnesia, and high-grade chrome ore. Each batch is subjected to comprehensive chemical and physical analysis before being accepted into our production line.

- Automated Batching and Mixing: Computer-controlled systems ensure precise weighing and homogenous mixing of all components. This guarantees uniform chemical composition and physical properties throughout the entire production run, eliminating batch-to-batch variability.

- High-Tonnage Friction and Hydraulic Pressing: We utilize advanced, high-pressure presses to form the bricks. This critical step achieves maximum density and dimensional accuracy, which are essential for tight furnace linings and resistance to slag infiltration.

- Precision-Controlled Tunnel Kiln Firing: The pressed bricks are fired in long, high-temperature tunnel kilns with meticulously controlled temperature curves. This slow, precise firing process is vital for developing the strong, direct-bonded microstructure that gives our bricks their signature strength and stability.

- Comprehensive Quality Assurance: Quality is not just a final check; it’s embedded in our process. From in-process monitoring of dimensions and density to final laboratory testing of CCS, porosity, and thermal properties, every HANI brick is certified to perform.

Frequently Asked Questions (FAQ)

What is the primary difference between direct-bonded and fused-rebonded magnesia chrome bricks?

The main difference lies in the raw materials and resulting microstructure. Direct-bonded bricks are made from sintered raw materials fired at high temperatures to create direct crystalline bonds. Fused-rebonded bricks are made from pre-melted (fused) grains, which are then pressed and fired. This fusion process creates a much denser, less porous, and more chemically stable raw material, leading to a final product with significantly superior resistance to slag penetration and erosion, making it suitable for the most aggressive industrial environments.

How does the Cr₂O₃ content affect the brick’s properties?

Chromium trioxide (Cr₂O₃) plays a crucial role. Increasing Cr₂O₃ content generally improves thermal shock resistance due to the formation of the flexible spinel phase and the creation of microcracks that dissipate stress. It also increases the viscosity of penetrating silicate slags, which enhances corrosion resistance. However, very high Cr₂O₃ content can sometimes reduce refractoriness under load. The optimal percentage depends entirely on the specific application, balancing thermal shock needs with slag chemistry and operating temperature.

Are there environmental considerations with magnesia chrome bricks?

Yes, the potential formation of hexavalent chromium (Cr⁶⁺) is a known environmental and health concern associated with chrome-bearing refractories. Reputable manufacturers like HANI address this seriously. We utilize high-purity, low-silica raw materials and precisely control the firing atmosphere and temperature to minimize the formation of Cr⁶⁺. Furthermore, for certain applications, we are actively developing and promoting high-performance magnesia-spinel and other chrome-free alternatives to provide environmentally responsible solutions without compromising performance.

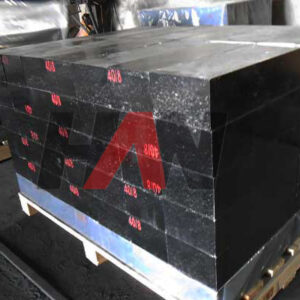

How should Magnesia Chrome Bricks be stored on-site before installation?

Proper storage is crucial to maintain the integrity of the bricks. They should be stored in a dry, covered area, preferably on their original pallets, to protect them from rain, snow, and ground moisture. Magnesia-based refractories can be susceptible to hydration if exposed to water for prolonged periods, which can compromise their strength. The original plastic shrink-wrap should be kept intact for as long as possible before use.