Description

High-performance refractory solution for extreme thermal and chemical environments in steelmaking and metallurgical applications.

Material Composition and Scientific Basis

The performance of Magnesia Dolomite Carbon Bricks is rooted in their carefully balanced chemical composition. Each component plays a distinct role in enhancing the overall functionality of the refractory system:

- Magnesia (MgO): Sourced from fused or sintered magnesia with purity levels above 96%, it provides excellent resistance to basic slags and high refractoriness. MgO has a melting point of approximately 2852°C, making it one of the most thermally stable oxides used in refractories.

- Dolomite (CaO·MgO): Naturally occurring or calcined dolomite contributes both CaO and MgO. The presence of CaO improves slag compatibility, especially in environments where lime-rich slags dominate. However, free CaO is prone to hydration, so stabilization through low-temperature calcination or protective coatings is essential.

- Carbon (Graphite): High-purity flake graphite (typically 10–18%) is added to improve thermal shock resistance and reduce slag penetration. Carbon lowers the wettability of the brick surface by molten phases, thereby minimizing erosion. It also increases thermal conductivity, allowing for more uniform heat distribution and reduced thermal gradients.

- Bonding Agents: Resin binders such as phenolic resin are used to hold the granular mix together before firing. These binders carbonize during heat-up, forming a carbon network that enhances structural cohesion.

- Antioxidants: Additives like aluminum, silicon, or boron carbide are incorporated to inhibit oxidation of carbon at high temperatures. These form protective layers (e.g., Al4C3, SiC) that shield the carbon phase from atmospheric oxygen and CO2.

The microstructure of these bricks features a dense matrix of magnesia and dolomite grains embedded in a carbon-rich network. This dual-phase structure allows the material to resist both chemical attack and mechanical degradation over extended service periods.

Technical Specifications and Performance Data

HANI’s Magnesia Dolomite Carbon Bricks are manufactured under strict quality control standards to ensure consistency across batches. Below is a detailed table outlining the typical physical and chemical properties of standard grades:

| Property | Unit | Typical Value (Grade MDC-15) | Test Method |

|---|---|---|---|

| MgO Content | % | ≥ 65 | GB/T 5069 |

| CaO Content | % | ≥ 12 | GB/T 5069 |

| C (Graphite) Content | % | 15 ± 1 | GB/T 1424 |

| Bulk Density | g/cm³ | ≥ 2.90 | GB/T 2997 |

| Apparent Porosity | % | ≤ 14 | GB/T 2997 |

| Cold Crushing Strength | MPa | ≥ 45 | GB/T 5072 |

| Modulus of Rupture (Room Temp) | MPa | ≥ 14 | GB/T 3001 |

| Thermal Conductivity (1000°C) | W/m·K | 8.5 – 10.2 | ASTM C468 |

| Reheating Dimensional Change (1400°C, 3h) | % | ±0.3 | GB/T 7320 |

These values are representative of standard production runs. Custom formulations are available upon request to meet specific furnace conditions, including higher carbon content (up to 20%) or enhanced antioxidant systems for ultra-high-temperature applications.

Manufacturing Process and Quality Assurance

The production of Magnesia Dolomite Carbon Bricks involves a multi-stage process that ensures homogeneity, density, and structural integrity:

- Raw Material Selection: Only high-purity magnesia (≥96% MgO), stabilized dolomite, and natural flake graphite (≥95% C) are used. All materials undergo strict incoming inspection for chemical composition and particle size distribution.

- Proportioning and Mixing: Raw materials are weighed according to precise formulations. Antioxidants such as Al, Si, or B4C are added in controlled amounts. The mixture is blended in high-intensity mixers to ensure uniform dispersion.

- Forming: The mixed batch is pressed in hydraulic presses at pressures exceeding 200 MPa to achieve high green density and dimensional accuracy. Isostatic pressing may be used for complex shapes or critical applications.

- Drying: Green bricks are dried slowly in controlled-temperature chambers (80–120°C) to remove moisture without causing cracks or warping.

- Heat Treatment: Unlike traditional fired bricks, Magnesia Dolomite Carbon Bricks are typically not fired above 300°C to preserve the carbon structure. Instead, they are cured to carbonize the resin binder, forming a thermoset network.

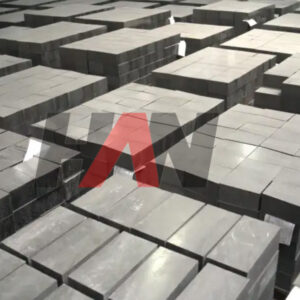

- Finishing and Inspection: Bricks are machined to precise tolerances if required. Each unit undergoes visual inspection, dimensional checks, and non-destructive testing (e.g., ultrasonic scanning) to detect internal flaws.

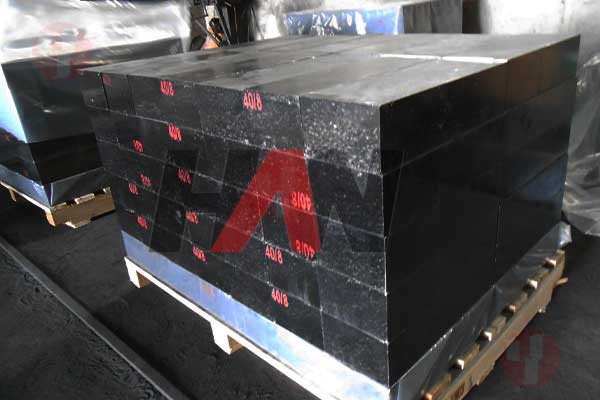

- Packaging: Finished bricks are wrapped in moisture-resistant film and palletized for shipment. Desiccants are included to prevent hydration of free CaO during storage.

HANI implements a full ISO 9001-compliant quality management system. Every batch is traceable, and test reports are provided with shipments. Third-party certification can be arranged upon customer request.

Applications in Metallurgical Industry

Magnesia Dolomite Carbon Bricks are primarily used in areas of steelmaking equipment where both high thermal load and chemical attack are present. Key applications include:

- Basic Oxygen Furnace (BOF) Lining: Especially in the slag line and trunnion areas where lime-rich slag causes severe erosion. The high CaO content in dolomite improves slag compatibility, reducing dissolution rates.

- Electric Arc Furnace (EAF) Walls and Roofs: Used in the hot zone where frequent scrap charging leads to thermal cycling. The carbon content helps absorb thermal stress and prevents cracking.

- Steel Ladle Slag Line: In ladles handling high-alloy steels or secondary refining, where slag basicity is high. The bricks resist penetration by CaO-SiO2-Al2O3-FeO slags.

- Vacuum Degassers and RH Units: Where low-pressure environments increase the risk of carbon oxidation. Antioxidant-enhanced versions are recommended.

- Tundish Impact Zones: For tundishes using MgO-based coatings or monolithic linings, pre-formed bricks offer longer service life.

Field data from multiple steel plants indicate that HANI’s Magnesia Dolomite Carbon Bricks can extend campaign life by 15–25% compared to conventional magnesia-carbon bricks, particularly in high-slag environments. This translates into reduced relining frequency, lower maintenance costs, and improved furnace availability.

Installation and Handling Guidelines

Proper installation is crucial to maximizing the service life of Magnesia Dolomite Carbon Bricks. The following best practices should be observed:

- Store bricks in a dry, covered area with relative humidity below 60% to prevent hydration of free CaO in dolomite.

- Use only phosphate-bonded or carbon-containing mortars compatible with basic refractories. Avoid water-based mortars that can initiate premature hydration.

- Ensure tight joints with uniform mortar thickness (2–3 mm). Excessive gaps can lead to slag infiltration.

- Follow the manufacturer’s recommended heating schedule during furnace start-up. A gradual ramp-up (e.g., 50–100°C/hour) minimizes thermal stress and allows for controlled carbonization of binders.

- Avoid rapid cooling or water quenching during shutdowns, as this can induce thermal shock and spalling.

- Inspect the lining regularly during operation using borescopes or laser profiling to detect wear patterns early.

HANI provides technical support for installation supervision and furnace commissioning. On-site training for maintenance teams is also available upon request.

Frequently Asked Questions (FAQ)

Environmental and Safety Considerations

While Magnesia Dolomite Carbon Bricks are inert during normal operation, certain precautions should be taken during handling and installation:

- Wear gloves and dust masks when cutting or grinding bricks to avoid inhalation of fine particles.

- Graphite dust is combustible; keep away from open flames and sparks.

- Used bricks may contain trapped metals or slag residues. Dispose of according to local industrial waste regulations.

- The production process at HANI follows strict environmental protocols, including dust collection systems and energy-efficient curing ovens.

Recycling of spent refractories is encouraged. Crushed bricks can be reused as aggregate in new refractory mixes or as landfill cover, depending on contamination levels.

Long-Term Performance and Industry Feedback

Over the past decade, HANI’s Magnesia Dolomite Carbon Bricks have been deployed in over 40 steel plants across Asia, the Middle East, and South America. Customer feedback consistently highlights improvements in lining longevity, reduced maintenance frequency, and better process stability.

One integrated steel mill in India reported an increase in BOF campaign life from 4,200 heats to 5,100 heats after switching to HANI’s MDC-15 grade. Another plant in Turkey observed a 20% reduction in ladle relining costs due to extended slag line durability.

Continuous R&D efforts focus on improving oxidation resistance through nano-additives and optimizing particle packing density for even lower porosity. Field trials with boron-modified grades show promising results in vacuum metallurgy applications.