Description

Mastering High-Temperature Environments with Advanced Magnesite Bricks

In the relentless world of high-temperature industrial processes, where thermal and chemical stresses push materials to their absolute limits, the choice of refractory lining is paramount. Magnesite bricks stand as a cornerstone solution, engineered to withstand the most extreme conditions found in steelmaking, non-ferrous metallurgy, cement production, and glass manufacturing. These basic refractory products, primarily composed of magnesium oxide (MgO), offer unparalleled resistance to basic slags and high temperatures, ensuring operational stability, extending campaign life, and enhancing overall process efficiency. Their reliability is not just a feature; it’s a fundamental requirement for modern industrial furnaces.

At HANI, we leverage decades of refractory expertise to produce magnesite bricks that don’t just meet industry standards but redefine them. By combining premium-grade raw materials with state-of-the-art manufacturing technologies, we deliver a product line characterized by superior density, low porosity, and exceptional thermomechanical strength. This guide provides a comprehensive exploration of magnesite bricks, their properties, manufacturing processes, and critical applications, offering valuable insights for engineers, procurement managers, and furnace operators seeking optimal refractory performance.

The Foundation of Performance: Understanding Magnesite Brick Composition

The exceptional performance of magnesite bricks originates from their primary constituent: periclase. Periclase is the crystalline form of magnesium oxide (MgO), a mineral with an extremely high melting point of approximately 2800°C (5072°F). The manufacturing journey begins with natural magnesite ore (MgCO₃) or synthetic magnesia derived from seawater or brines. This raw material undergoes a critical high-temperature calcination process known as dead-burning, typically in rotary or shaft kilns at temperatures ranging from 1500°C to 2000°C.

This intense heating process drives off carbon dioxide (CO₂) and sinters the MgO into dense, stable, and chemically inert periclase crystals. The quality of the final brick is directly influenced by the purity of the raw magnesite and the precision of the calcination process. Impurities such as silica (SiO₂), lime (CaO), and iron oxide (Fe₂O₃) can form lower-melting-point silicate phases within the brick’s microstructure, potentially compromising its high-temperature performance. Therefore, meticulous raw material selection and process control are non-negotiable for producing high-performance magnesite refractories.

Classifications of Magnesite Bricks: A Spectrum of Solutions

Magnesite bricks are not a one-size-fits-all solution. They are categorized based on their manufacturing method and chemical purity, each tailored for specific operational demands. The two primary categories are Sintered Magnesite Bricks and Fused Magnesite Bricks.

1. Sintered Magnesite Bricks (Dead-Burned Magnesite Bricks)

These are the most common type of magnesite refractory. They are produced by pressing dead-burned magnesite clinker into the desired shape, followed by firing in a tunnel kiln at temperatures between 1550°C and 1750°C. This final firing step creates strong ceramic bonds between the periclase grains, resulting in a durable and robust brick structure.

- Key Characteristics: Good high-temperature performance, excellent resistance to basic slag, and high refractoriness.

- Common Applications: Permanent linings of steelmaking furnaces (EAF, BOF), ladles, tundishes, cement rotary kilns, and glass furnace regenerators.

2. Fused Magnesite Bricks (Rebonded Fused Magnesite Bricks)

For the most demanding applications, fused magnesite bricks offer a significant upgrade in performance. They are manufactured using fused magnesia as the primary raw material. Fused magnesia is produced by melting high-purity dead-burned magnesite in an electric arc furnace at temperatures exceeding 2800°C. This process yields large, well-developed periclase crystals with very high density and low impurity levels. The cooled, crushed fused magnesia is then formed and fired at very high temperatures to create a rebonded brick.

- Key Characteristics: Superior density, extremely low porosity, large crystal structure, and exceptional resistance to corrosion and erosion by aggressive slags.

- Common Applications: Critical wear areas such as the slag line in steel ladles and EAFs, AOD converters, and in applications involving highly corrosive environments.

Technical Specifications of HANI Magnesite Bricks

The performance of a magnesite brick is defined by a combination of its chemical and physical properties. The following table details the typical specifications for our core range of HANI magnesite bricks, demonstrating our commitment to transparency and quality. Selecting the appropriate grade is crucial for optimizing furnace performance and achieving cost-effectiveness.

| Property | Unit | Sintered Magnesite Bricks | Fused Magnesite Bricks | ||||

|---|---|---|---|---|---|---|---|

| Grade | HNM-92 | HNM-95 | HNM-96 | HFM-97 | HFM-98 | HFM-98Z | |

| MgO | % ≥ | 92.0 | 95.0 | 96.0 | 97.0 | 98.0 | 96.5 |

| CaO | % ≤ | 2.5 | 1.8 | 1.5 | 1.0 | 0.8 | 0.9 |

| SiO₂ | % ≤ | 3.5 | 2.0 | 1.5 | 0.8 | 0.5 | 0.6 |

| ZrO₂ | % | – | – | – | – | – | ≥ 1.5 |

| Bulk Density | g/cm³ ≥ | 2.90 | 2.95 | 2.98 | 3.02 | 3.05 | 3.08 |

| Apparent Porosity | % ≤ | 16 | 15 | 14 | 14 | 13 | 13 |

| Cold Crushing Strength | MPa ≥ | 60 | 70 | 75 | 80 | 85 | 90 |

| Refractoriness Under Load (0.2MPa) | °C ≥ | 1550 | 1600 | 1650 | 1700 | 1700 | 1720 |

Industrial Applications: Where Performance is Critical

The unique properties of magnesite bricks make them indispensable in a wide array of high-temperature industrial sectors.

- Steel and Iron Industry: This is the largest consumer of magnesite refractories. They are extensively used for lining Basic Oxygen Furnaces (BOF), Electric Arc Furnaces (EAFs), and Ladle Furnaces (LFs). In EAFs, they are critical for sidewalls, especially at the slag line, and for tap-hole construction. Their resistance to iron-oxide-rich basic slag is vital for furnace integrity.

- Cement Manufacturing: Magnesite bricks are the preferred lining for the high-temperature burning zone of rotary cement kilns. This zone experiences extreme thermal loads and chemical attack from the clinker. The bricks’ ability to form a stable coating and resist the alkaline environment is crucial for long kiln campaigns.

- Non-Ferrous Metallurgy: Furnaces and converters used in the smelting of copper, nickel, lead, and other non-ferrous metals rely on magnesite bricks to handle corrosive slags and high operating temperatures. They are used in reverberatory furnaces, converters, and anode furnaces.

- Glass Production: In glass melting furnaces, magnesite bricks are used in the regenerator chambers. Their role is to absorb and release heat efficiently. They are particularly valued for the upper courses of the checkerwork due to their high-temperature stability and resistance to the volatile components in the furnace atmosphere.

Frequently Asked Questions (FAQ)

What is the primary advantage of fused magnesite bricks over sintered ones?

The primary advantage lies in the microstructure. Fused magnesite bricks are made from electro-fused magnesia, which has larger, more developed periclase crystals and a much denser structure. This results in significantly lower porosity and higher resistance to slag penetration and corrosion. While more expensive, they offer a much longer service life in highly aggressive environments like the slag line of a steel ladle, making them more cost-effective in the long run for critical applications.

How does the CaO/SiO₂ ratio affect the performance of magnesite bricks?

The ratio of lime (CaO) to silica (SiO₂) is a critical parameter that influences the properties of the silicate bonding phase within the brick. A higher CaO/SiO₂ ratio (ideally above 2.0) promotes the formation of high-melting-point phases like dicalcium silicate (C₂S) and tricalcium silicate (C₃S). These phases are stable at high temperatures. A low ratio can lead to the formation of lower-melting-point phases like monticellite (CMS) and forsterite (M₂S), which can liquefy at operating temperatures, reducing the brick’s hot strength and slag resistance. HANI’s manufacturing process carefully controls this ratio to maximize high-temperature performance.

Why is thermal shock resistance a concern for magnesite bricks?

Magnesite bricks have a relatively high coefficient of thermal expansion and lower thermal conductivity compared to some other refractories. This makes them susceptible to thermal spalling, which is cracking or flaking caused by rapid temperature changes. This is a significant concern in applications with intermittent operations or rapid heating/cooling cycles. To mitigate this, proper pre-heating schedules are essential. For applications requiring enhanced thermal shock resistance, magnesia-spinel or magnesia-chrome bricks are often recommended.

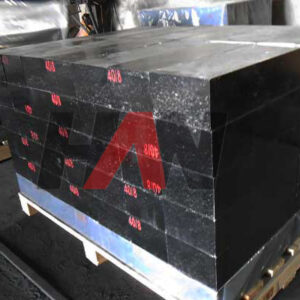

How should magnesite bricks be stored on-site?

Magnesite bricks are susceptible to hydration (reacting with moisture from the air), which can cause them to expand and crack, losing their strength. Therefore, they must be stored in a dry, covered environment, away from direct contact with the ground. Pallets should be shrink-wrapped, and any damaged packaging should be repaired immediately. It is recommended to follow a “first-in, first-out” inventory system to ensure bricks are used in a timely manner.

Engineered for Endurance and Reliability

Choosing the right refractory is a critical investment in your operational success. It directly impacts furnace availability, maintenance costs, product quality, and safety. Our comprehensive range of magnesite bricks is engineered to provide robust, reliable, and long-lasting performance in the face of extreme industrial challenges. By partnering with a knowledgeable supplier, you gain access not only to superior products but also to the technical expertise required to select, install, and maintain your refractory linings for optimal results.

We are dedicated to advancing refractory technology and providing solutions that empower our clients to push the boundaries of their high-temperature processes. We invite you to explore how our high-performance magnesite bricks can bring enhanced durability and efficiency to your operations.