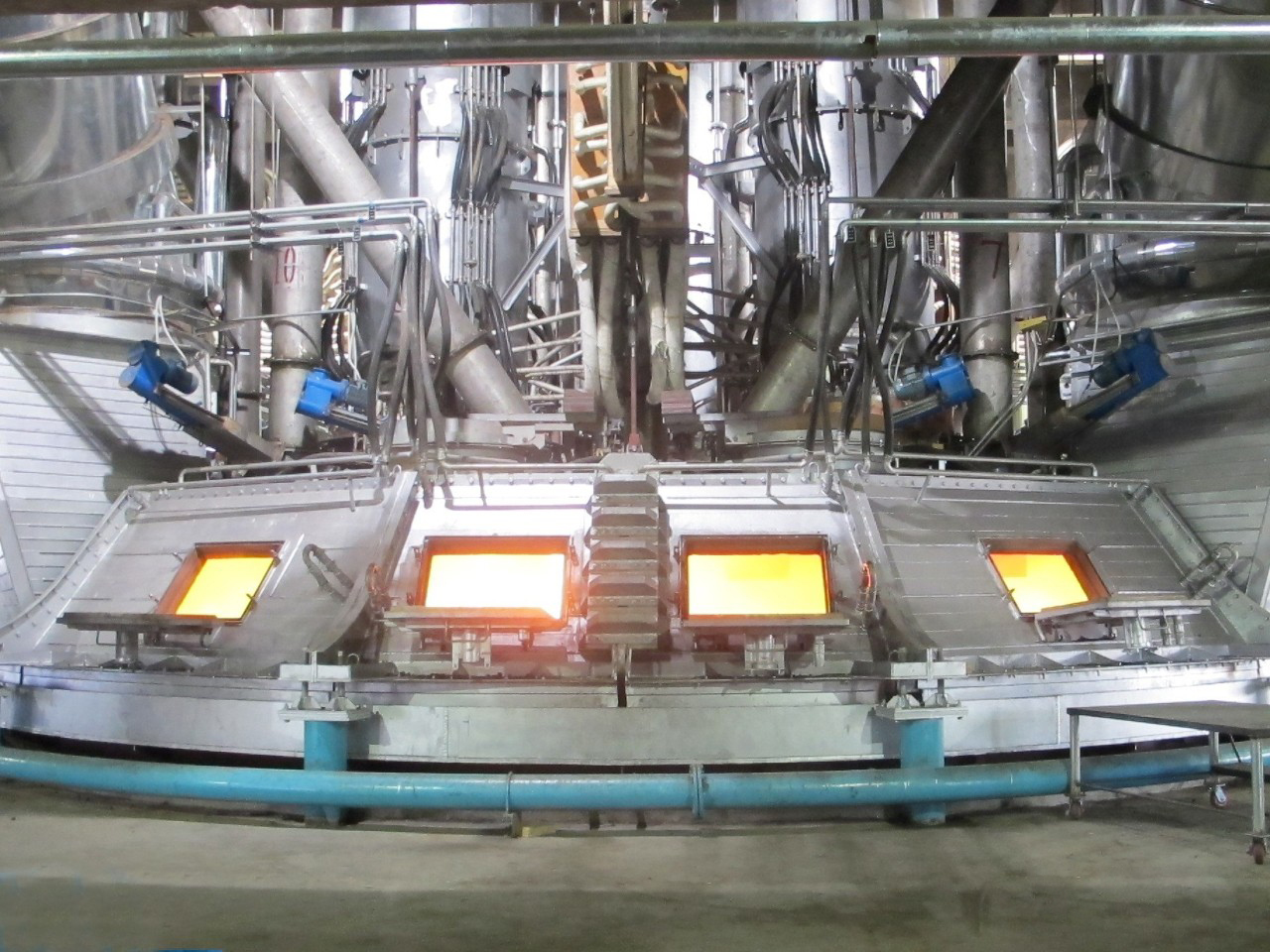

The Submerged Arc Furnace (SAF), often abbreviated as SAF, is an important equipment in the field of ferroalloy production. It plays a particularly important role in processes such as ferrochrome production and ferrosilicon furnace operations.

The working principle of a submerged arc furnace is quite unique. In this furnace, electric arcs are formed beneath a layer of charge material. These arcs generate intense heat, which is essential for the smelting process. As the arcs heat the material, a chemical reaction occurs, which results in the formation of ferroalloys.

During the operation of a SAF, several factors need to be carefully monitored. One of the key aspects is the power factor. A high power factor is ideal as it ensures efficient energy utilization. The furnace operator must constantly adjust the electrical parameters to maintain an optimal power factor.

The design of a submerged arc furnace is also crucial. It needs to be designed in a proper manner so that the heat is properly distributed and it operates efficiently. The shape of the furnace, the arrangement of the electrodes, and the refractory lining all have an impact on its overall performance.

In the ferroalloy production process, raw materials such as iron ore, coke, and other necessary additives are charged into the furnace. Once inside the furnace, the heat generated by the submerged arc melts and combines these materials to form a ferroalloy. For example, in ferrochrome production, a proper mix of chromite ore and reducing agents are processed in the SAF to obtain the desired ferrochrome alloy.

The price of ferroalloys produced in a submerged arc furnace is influenced by a variety of factors. The cost of raw materials, energy consumption during operation, and the overall efficiency of the furnace all play a role. In addition, market demand and supply dynamics also have a significant impact on prices.

In summary, the submerged arc furnace is the cornerstone of ferroalloy production. Understanding the working principle, operation, design and process of the submerged arc furnace is essential to ensure the efficient and economic production of high-quality ferroalloys in the global market.