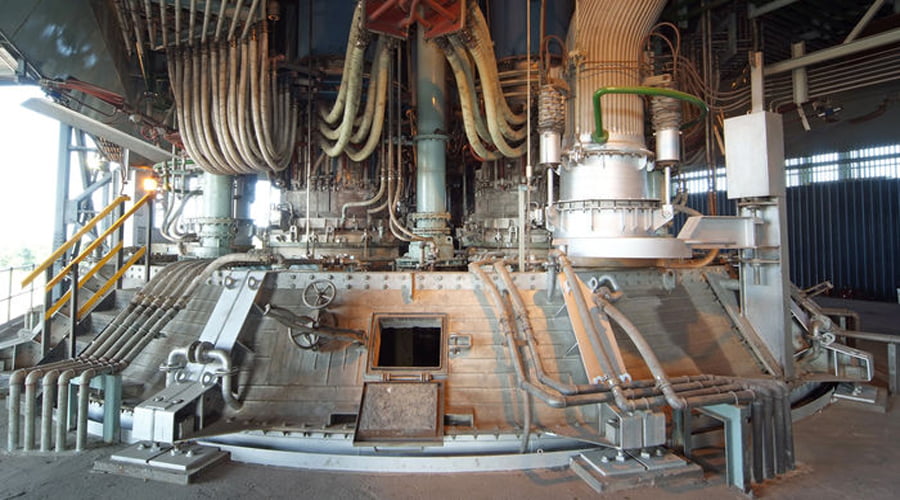

Submerged Arc Furnace Operation Matters

Submerged Arc Furnaces (SAF) play a vital role in various industries including steelmaking and mineral processing. These furnaces use a unique operating principle where the electrodes and arc zone are immersed beneath a layer of slag or metal. The success of a SAF operation depends on several key factors, which must be carefully considered and managed to ensure optimum performance and productivity.

Features

Characteristics of Submerged Arc Furnace Operation

a) One of the main considerations for SAF operation is the selection of appropriate electrode materials.

The electrodes act as the conducting medium that creates the arc within the furnace. The choice of electrode material depends on factors such as desired heat transfer efficiency, electrical conductivity, and resistance to chemical reactions with the furnace environment.

Common electrode materials include graphite, carbon, and various refractory metals. Selecting the correct electrode material is critical to achieving stable and efficient operation.

b) Maintaining the correct electrode position within the furnaces is another critical aspect.

Electrodes must be placed at optimal depths to ensure efficient energy transfer and electrode consumption. If the electrodes are too shallow, they may not generate enough heat, resulting in poor metal or slag heating.

Conversely, if they are too deep, excessive electrode consumption and energy loss may occur. Periodic monitoring and adjustment of electrode positions are necessary to maintain ideal operating conditions.

c) Slag chemistry is another important consideration in submerged arc furnace operation.

The composition and properties of the slag affect various aspects of the process, including heat transfer, chemical reactions and metal recovery. Well-controlled slag chemistry can increase furnace energy efficiency, increase metal recovery, and minimize electrode wear.

Monitoring and adjusting slag chemistry to optimize operations through proper selection and addition of additives is critical.

d) Temperature control is a critical aspect of SAF operation.

The required operating temperature range depends on the specific application and the material being processed. Maintaining the proper temperature is critical to achieving the desired product quality while minimizing energy consumption and electrode wear.

Advanced temperature control systems, such as infrared sensors and thermocouples, are used to precisely monitor and regulate furnace temperature.

e) Proper maintenance and regular cleaning of your submerged arc furnaces is critical to ensuring its longevity and efficient operation.

Accumulation of impurities, solidified metal, or slag deposits can impede heat transfer, affect electrode positioning, and promote undesirable chemical reactions. Cleaning procedures such as slagging and lining maintenance should be performed regularly to remove these deposits and ensure smooth operation.

In summary, the successful operation of a submerged arc furnace depends on a variety of factors for accurate and careful management of the submerged arc furnaces. Proper electrode material selection, electrode positioning, slag chemistry control, temperature regulation and regular maintenance are all critical to achieving optimum performance and productivity.

By focusing on these key aspects, industries can maximize the efficiency of SAF and achieve their desired production goals.