In the steelmaking industry, maintaining the temperature of equipment is crucial for ensuring efficiency, quality, and safety. Two key devices used for this purpose are the Tundish Preheater and the Ladle Preheater. While both serve the purpose of preheating, they are designed for different stages of the steelmaking process. This article explores the principles, differences, and technical parameters of these devices.

What is a Tundish Preheater?

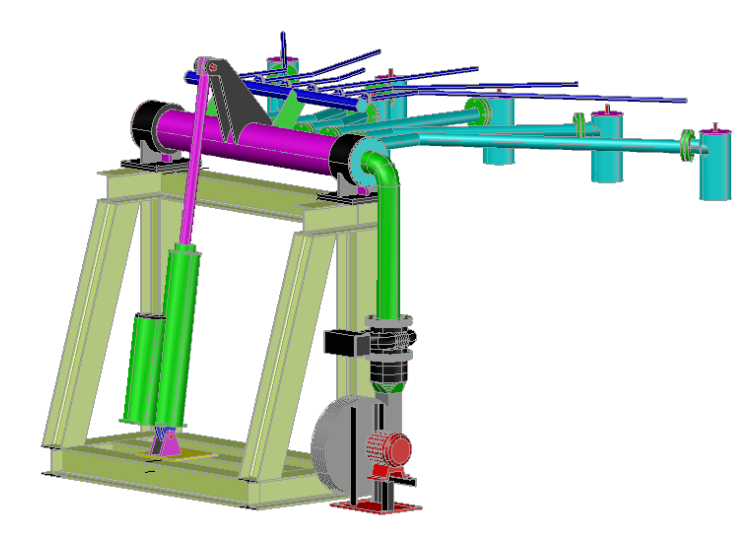

A Tundish Preheater is a device used to heat the tundish before it receives molten metal. The tundish is a refractory-lined container that acts as an intermediary between the ladle and the continuous casting machine. Its primary function is to distribute molten steel evenly and control the flow rate during casting.

Principle: The Tundish Preheater uses burners or electric heating elements to raise the temperature of the tundish to a specific level, typically between 800°C and 1200°C. This preheating process prevents thermal shock when molten steel is poured into the tundish, reduces energy loss, and minimizes the risk of defects in the final product.

What is a Ladle Preheater?

A Ladle Preheater is designed to heat the ladle, which is a large vessel used to transport molten steel from the furnace to the tundish or casting area. The ladle is also lined with refractory materials to withstand high temperatures.

Principle: The Ladle Preheater uses gas burners or electric heating systems to heat the ladle to temperatures ranging from 600°C to 1000°C. Preheating the ladle ensures it is at the optimal temperature to handle molten steel, reduces heat loss during transportation, and improves the overall efficiency of the steelmaking process.

Key Differences Between Tundish Preheater and Ladle Preheater

While both devices serve the purpose of preheating, they differ in their applications, design, and operational parameters:

- Application: The Tundish Preheater is used for the tundish in the continuous casting process, while the Ladle Preheater is used for the ladle during molten steel transportation.

- Temperature Range: The Tundish Preheater typically operates at higher temperatures (800°C–1200°C) compared to the Ladle Preheater (600°C–1000°C).

- Design: The Tundish Preheater is often smaller and more compact, while the Ladle Preheater is larger to accommodate the size of the ladle.

- Heating Method: Both devices use burners or electric heating, but the Tundish Preheater may require more precise temperature control due to its role in continuous casting.

Technical Parameters of Tundish Preheater and Ladle Preheater

Below is a detailed comparison of the technical parameters for Tundish Preheater and Ladle Preheater:

| Parameter | Tundish Preheater | Ladle Preheater |

|---|---|---|

| Temperature Range | 800°C–1200°C | 600°C–1000°C |

| Heating Method | Gas Burners / Electric Heating | Gas Burners / Electric Heating |

| Heating Time | 30–60 minutes | 60–120 minutes |

| Energy Consumption | 50–100 kWh | 100–200 kWh |

| Capacity | 1–5 tons | 50–200 tons |

| Fuel Type | Natural Gas / Propane | Natural Gas / Propane |

| Control System | Automated / Manual | Automated / Manual |

| Refractory Lining | High Alumina / Magnesia | High Alumina / Magnesia |

| Dimensions | 2m x 1.5m x 1.5m | 5m x 3m x 3m |

| Weight | 500–1000 kg | 5000–10000 kg |

| Maintenance Interval | Every 3 months | Every 6 months |

| Cost | $10,000–$50,000 | $50,000–$200,000 |

Conclusion

Both the Tundish Preheater and the Ladle Preheater play critical roles in the steelmaking process by ensuring that equipment is at the optimal temperature to handle molten metal. While the Tundish Preheater focuses on the tundish in continuous casting, the Ladle Preheater is designed for the ladle during transportation. Understanding their principles, differences, and technical parameters is essential for optimizing steel production and maintaining high-quality standards.

By investing in advanced preheating technologies, steel manufacturers can improve efficiency, reduce energy consumption, and minimize defects in the final product. Whether it’s the Tundish Preheater or the Ladle Preheater, both devices are indispensable in modern steelmaking operations.

We can also design, manufacture, transform and upgrade existing smelting production equipment according to user requirements.

Services

For the design and manufacture of tundish preheaters and ladle preheaters, HANI Metallurgy can provide “turnkey” services such as design drawings and plans, workshop layout, equipment manufacturing, installation and commissioning according to customer requirements. HANI has more than 20 years of experience in metallurgical equipment manufacturing, serving more than 50 steel manufacturers around the world and has accumulated rich project experience.