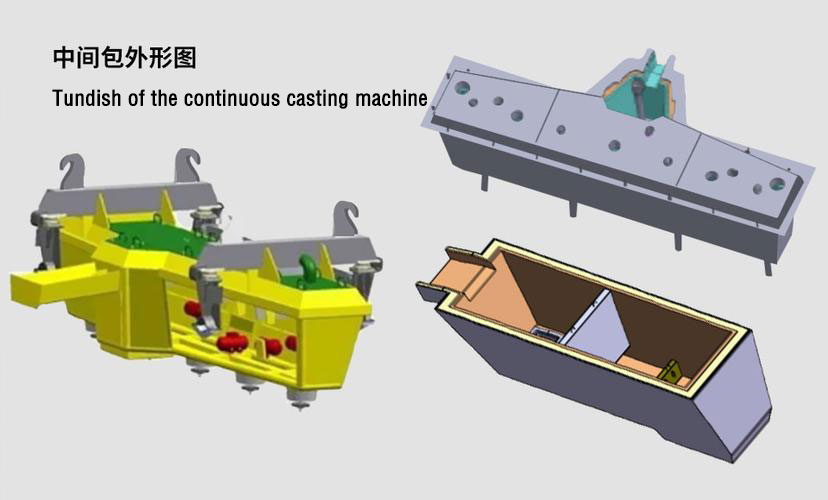

Tundish of the continuous casting machine is an important component in the production process of the continuous casting machine, which carries the heavy responsibility of steelmaking in the steelmaking plant. A tundish is a device used to store molten steel and transport it to the crystallizer of a continuous casting machine, playing a crucial role in the steelmaking process.

Firstly, the intermediate ladle has the function of storing molten steel. In the steelmaking process, the steel liquid needs to go through multiple processes and treatments to obtain the required finished steel. Therefore, the intermediate ladle can effectively store molten steel for supply to the continuous casting machine when needed. This storage function can ensure continuous production of the continuous casting machine and improve work efficiency.

Secondly, the intermediate ladle can regulate the temperature and composition of the steel liquid. The temperature and composition of the molten steel have a significant impact on the quality of the finished steel during the production process of the continuous casting machine. The intermediate ladle can control the cooling rate and heating method of the steel liquid to achieve the desired temperature range. Meanwhile, the intermediate ladle can also adjust the composition of the steel liquid by adding appropriate alloying elements to meet the production needs of different types of steel.

In addition, the intermediate package also has filtering and impurity removal functions. In the steelmaking process, the steel liquid often contains impurities and non-metallic inclusions, which have adverse effects on the quality and performance of the steel. By installing a filtering device in the intermediate package, these impurities and inclusions can be effectively removed, improving the quality of the finished steel.

In addition, the intermediate ladle can also control the flow and distribution of molten steel. In the production process of the continuous casting machine, the steel liquid needs to be evenly distributed to each crystallizer to ensure the uniformity of the finished steel. By designing reasonable flow channels and flow control devices, the intermediate package can evenly flow steel into various crystallizers, ensuring consistency in the quality and size of the finished steel.

In short, the tundish of the continuous casting machine is an indispensable and important equipment in the steelmaking process. It has multiple functions such as storing molten steel, adjusting temperature and composition, filtering impurities, controlling flow and distribution. The excellent design and use of the intermediate ladle are of great significance for ensuring the normal operation of the continuous casting machine and improving the quality of the finished steel. With the continuous development and innovation of technology, the performance and function of the intermediate ladle will also be further improved and perfected, making greater contributions to the development of the steelmaking industry.