Description

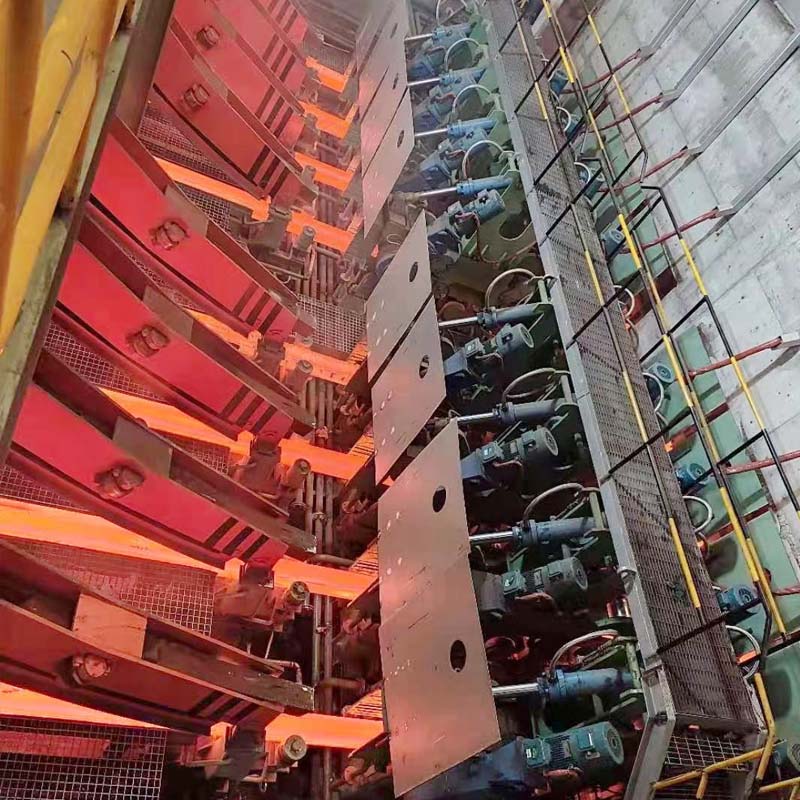

Full Arc Continuous Caster

Continuous Caster for Square Billet and Rectangular Billet

Continuous Caster for Square Billet and Rectangular Billet. The full arc continuous caster is composed of a ladle turret, tundish and conveying device, crystallizer, and vibration device, secondary cooling device, multi-roll tension leveler, dummy bar and its storage bench, dummy strip removal device, cutting head and collection device, billet cutting equipment, etc.

The mold of the full arc continuous caster is arc-shaped. The secondary cooling device forms an arc-shaped billet in the mold in a quarter of the arc. During the downward movement along with the arc roller table, it receives water spray cooling until it is completely solidified.

After full solidification, the billet enters the straightener at the horizontal tangent point, and then cut to a fixed length.

Parameter

Full Arc Continuous Caster Technological Parameters

Type of CCM: Full arc continuous caster for square billets and rectangular billet

Strands of CCM: 1, 2, 3, 4, 5, 6, 8, 10

The radius of CCM: 5.25m, 6m, 6.5m, 7m, 8m, 9m, 10m, 12m, 16m

Dimension of billet: Square billet: 120*120, 150*150, 180*180, 200*200, 240*240, 300*300mm

Rectangular billet: (120~200) *(240~600)mm

Round billet: Φ100~Φ450

Shaped blank: 500*300*85mm, 280*200*80mm

Drawing speed: 120*120 3.8m/min, 150*150 3.8m/min, 200*1200 3.8m/min

Annual output: 150000 ~ 200000 ton/strand

Overflow leakage rate: ≤ 0.1%

Continuous casting term: ≥ 8hW

Feature

Supporting mode of the ladle: Turret/ladle car

Tundish car: Full-suspending mode/half-suspending mode

Mould mode: Entirety copper tube type/parabolic taper

Control of casting strand: Auto-control of cesium-source liquid level

Vibration mode: Whole-leaf spring/Half-leaf spring/sine/non-sine

Secondary cooling mode: Gas-spray automatic water feeding /Full-water-cooling automatic water feeding

Straightening mode: Full-arc type five-roller continuous straightening/AC frequency control

Dummy mode: Self-adapting entirely rigidity dummy bar

Cutting mode: Narrow-slit high-efficiency automatic flame cutting machine/Hydraulic shear

Steel pushing mode: Mechanical elevated structure

Control mode: Controlled by PLC

Which can be switched between the automatic and manual drive

The arc continuous caster is arranged within the quarter arc range, so its height is lower than that of the vertical bending caster. This feature makes its equipment lighter, lower investment, and convenient for installation and maintenance.

Due to the low equipment height, the static pressure of molten steel borne by the billet during solidification is relatively small, which can reduce the internal crack and segregation caused by bulge deformation, which is conducive to improving the drawing speed and billet quality.

Customized Continuous Caster

We can design and manufacture the continuous caster according to the user’s steelmaking capacity, billet size, steel grade, and user site conditions. It can also be matched for manufacturers who already have continuous casting equipment.

Custom Range

Arc radius of casting machine: R2.5-10m

Billet species: square billet, round billet, slab, special-shaped billet

Continuous casting billet material: low carbon steel, low carbon alloy steel

Design production capacity: first-class 100,000 tons, second-class 200,000 tons, third-class 300,000 tons

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different needs

Production capacity can be adjusted according to customer requirements

Low energy consumption