Description

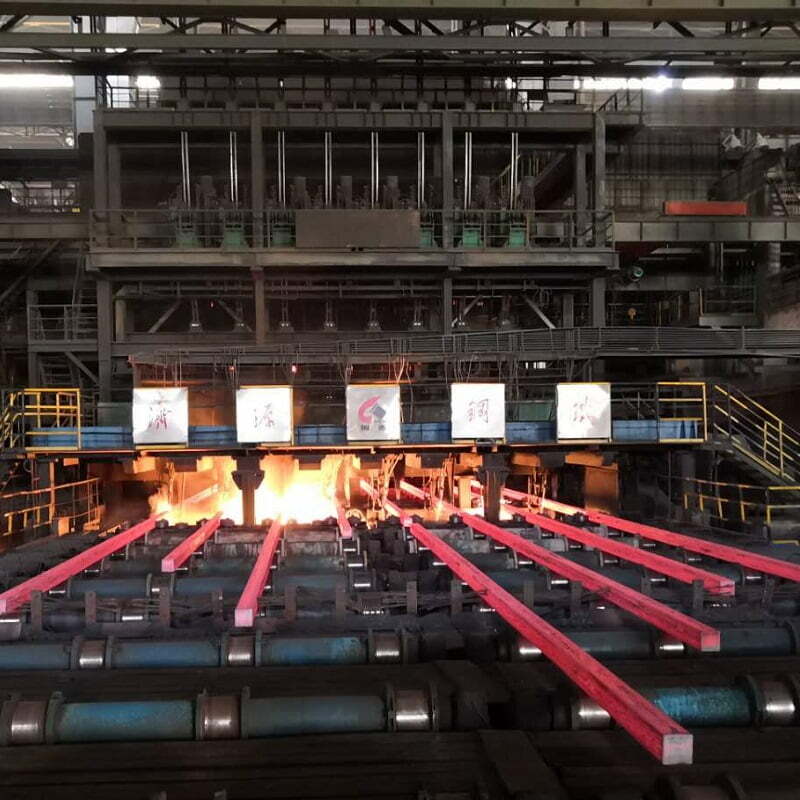

6 Strands R8.5 Full Arc Continuous Caster

At present, arc continuous caster is mainly used in small square billets and round billets below 150mm. Because the crystallizer is arc-shaped, the billet drawn out is also arc-shaped. The crystallizer and the secondary cooling section are configured on the quarter arc. Large radius arc continuous caster is selected as the model of a continuous casting machine, and continuous straightening technology.

Before being straightened, the billet moves downward along the arc and solidifies. It is straightened once with a five roller tension leveler in front of the vertical center tangent point.

When the billet is straightened, the inner arc extends outward and the outer arc is extruded inward. Because the five roller tension leveler is single-point straightening, in order to prevent cracks for billet breaking and internal damage, the deformation of the billet shall be controlled within the allowable deformation coefficient, and the arc radius shall be increased, which is the reason why the arc continuous caster is built.

Technology Application

Optimal Design

Advanced molten steel flow field technology is adopted in large smelting tundish

The molten steel level of the tundish is protected by double slag

The technology of multi furnace continuous firing

Continuous straightening technology

Equipped with automatic crystallizer powder adding system

Crystallizer hydraulic vibration technology is adopted

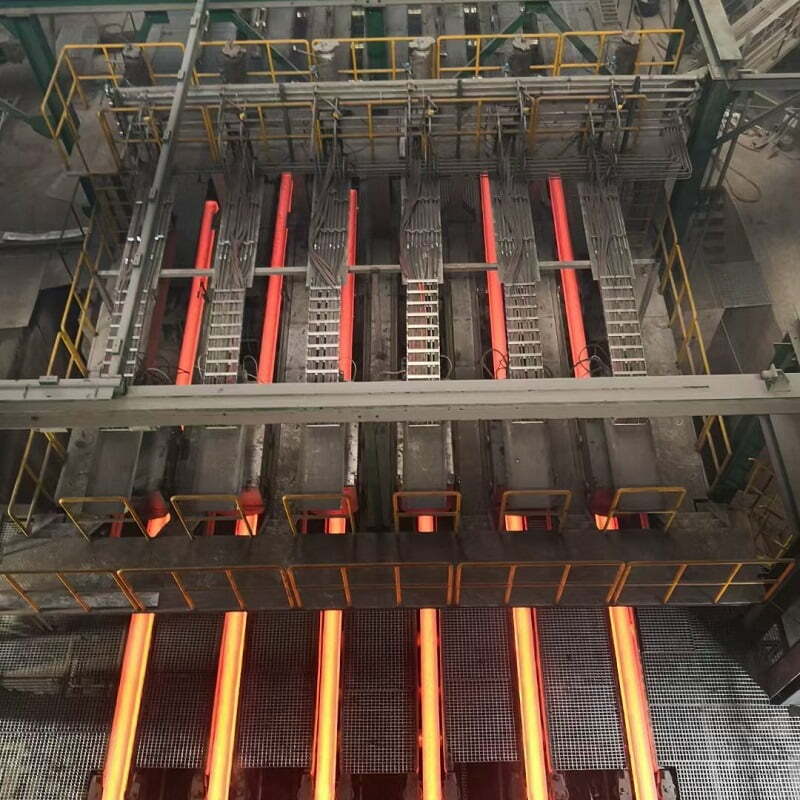

The secondary cooling zone adopts automatic control of air-water atomization cooling

The non-contact automatic sizing control technology is adopted to improve the sizing accuracy

The billet discharging mechanism adopts a two-way billet moving car and hydraulic step turnover cooling bed

Parameter

Parameter of 6 Strands R8.5 Full Arc Continuous Caster

|

Serial number

|

Item

|

Unit

|

Parameters

|

|

1

|

Model of arc continuous caster

|

Full rigid dummy bar, full arc type, continuous straightening

|

|

|

2

|

The basic radius of the caster

|

m

|

R8.5

|

|

3

|

Number of continuous casters × Stream number

|

Strands

|

1×6

|

|

4

|

Flow spacing

|

mm

|

900

|

|

5

|

Billet section size

|

mm

|

120×120、130×130、150×150、160×160

|

|

6

|

Fixed length

|

m

|

6.0~12.0

|

|

7

|

Cast steel grade

|

Ordinary carbon steel, low alloy structural steel

|

|

|

8

|

Length of crystallizer copper tube

|

mm

|

900

|

|

9

|

Crystallizer electromagnetic stirring

|

||

|

10

|

Ladle recasting equipment type

|

Two ladle cars are arranged horizontally

|

|

|

11

|

Tundish type

|

Recycling old equipment

|

|

|

12

|

Vibration type

|

Sinusoidal vibration of half leaf spring

|

|

|

13

|

The storage type of dummy bar

|

Cylinder driven, hydraulic tilting

|

|

|

14

|

Secondary cooling type

|

High pressure water atomization cooling

|

|

|

15

|

Automatic control of crystallizer liquid level

|

Recycling old equipment

|

|

|

16

|

Elevation of discharge roller surface

|

m

|

±0.000

|

|

17

|

Annual output of caster

|

t/a

|

80×(10×10×10×10)

|

Technical Advantages of Arc Continuous Caster

High Product Quality

Large radius arc continuous caster is selected as the model of a continuous casting machine, and continuous straightening technology is adopted to reduce the deformation rate of the continuous casting slab and prevent the surface and internal cracks of the slab.

Safe and Stable

The liquid steel level of the tundish is protected by double slag: the first layer adopts synthetic slag to isolate the liquid steel from the air and absorb floating inclusions; The second layer adopts natural slag (carbonized rice husk) to cover the synthetic slag for thermal insulation.

Automatic Protection Technology

Because the automatic equipment is added into the square and round billet arc continuous caster, the distribution uniformity of protective slag is realized by effectively controlling the addition speed of protective slag. In addition, the application scope of automatic protection technology also includes improving the lubrication conditions inside the mold and promoting the overall efficiency of production, so as to reduce the production risk and improve the overall profit

Automatic Mixing Technology

The application principle of automatic stirring technology mainly depends on electromagnetic stirring, so it reduces energy consumption. Compared with the use mode of traditional continuous caster, the electromagnetic stirrer at the end of secondary cooling also has the effect of expanding the axial crystal rate of the billet. It plays a certain role in improving the loose environment inside the billet and improving the effect of central segregation of the billet.

Improve Use Efficiency

In order to improve the use efficiency of equipment and reduce the operation intensity of workers, the ladle turret adopts an automatic positioning system. High speed, low speed, and parking space change-over switches can also be set on-site for manual control.

High Degree in Automation Control

Customized Continuous Caster

We can design and manufacture the continuous caster according to the user’s steelmaking capacity, billet size, steel grade, and user site conditions. It can also be matched for manufacturers who already have continuous casting equipment.

Custom Range

Arc radius of casting machine: R2.5-10m

Billet species: square billet, round billet, slab, special-shaped billet

Continuous casting billet material: low carbon steel, low carbon alloy steel

Design production capacity: first-class 100,000 tons, second-class second-class 200,000 tons, third-class third-class 300,000 tons

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different needs

Production capacity can be adjusted according to customer requirements

Low energy consumption