Description

Electric Arc Furnace Column Types

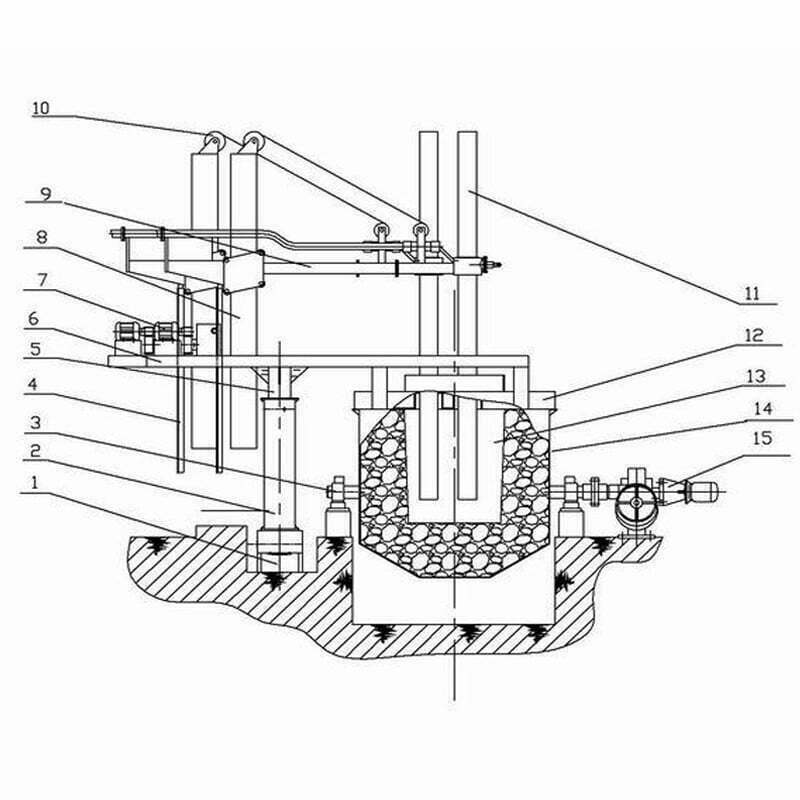

Electric arc furnace column

(1) Fixed column

The lower part of the fixed column is fixed on the lower platform of the rotating frame by the lower fixed support of the column.

The middle of the column is fixed on the upper platform of the revolving frame by the fixed support on the column. In order to increase the

Rigidity of the column, the upper ends of the three columns are connected by the fixed plate on the column.

A rail is welded on the column, and the trolley equipped with the electrode cross arm can move up and down on the rail.

Usually the fixed column is made of seamless steel pipe, and the lifting trolley track is welded on it. A cross-arm counterweight is installed inside the column.

(2) Lifting column

The lifting column uses bolts to connect the cross arm to the column.

By adjusting the bolts installed on the upper part of the upright column, the forward and backward movement of the cross arm and the horizontal rotation can be adjusted, as well as the lifting and lowering of the cross arm itself.

Therefore, it also has three-way rotation and three-way translation adjustment performance.

Advantage

The advantage of the electric arc furnace column is that the entire system of the lifting part has good rigidity, and under the same other conditions, it can be made lower than the fixed column.

The three uprights are not connected, the conductive tube is easier to arrange, and there is no closed magnetic circuit, so the electrical loss is small.

Therefore, most of the large and medium-sized electric arc furnaces use lifting columns.

The disadvantage is that the weight is heavier, especially when the mechanically driven lifting column is used, in order to reduce the driving force, adding a counterweight device increases the complexity of the structure.

Structural Characteristics

1. The shape of the electric arc furnace column

Common column shapes include circular columns and rectangular columns.

The circular column is welded with 2 rectangular rails 1 or V-shaped rails 4 on the seamless steel pipe.

The guide wheel used in the circular column occupies less space, and the stability of the column is relatively poorer than that of the rectangular column, and is generally used in the case of a small space.

The rectangular column is made by welding the steel plates 6 and 7 to the four square rails 5 by welding.

The used guide wheel occupies a large space, and the column has good stability, and is widely used in large and medium-sized electric arc furnaces.

2. Requirements for electric arc furnace column

(1) The length of the column should ensure that the electrode has enough travel, but it should not be too long.

(2) The column should have a certain lifting and lowering speed. At present, the rising speed of the column on the large electric furnace has reached 18m/min.

(3) The column must have sufficient strength and rigidity, and must not deform during use.

(4) The column guide is generally made of medium carbon steel and the surface is heat treated to increase wear resistance.

(5) For the fixed column, there must be a rotating device to adjust the column at the fixed point.

(6) For the lifting column, for the needs of maintenance, several round holes should be opened at the appropriate position in the height direction of the column.

3. Connection seat

The connecting seat refers to the connection part between the column and the cross arm, and the lower part of the connecting seat is welded with the column. The upper part and the cross arm are connected by bolts.

For the connection seat of the AC electric arc furnace transformer whose power is less than 15MV.A, the ordinary carbon structural steel with air cooling is generally used.

For the connection seat of the transformer with a power of 15~20MV-A, it is generally made of air-cooled non-magnetic steel.

For the connection seat with transformer power above 20MV . A, due to the large magnetic field strength, it is necessary to use water-cooled non-magnetic steel.

When the power of the transformer is above 40MV . A, the upper part of the electric arc furnace column and the connecting section of the connecting seat will also be very hot under the action of a strong electromagnetic field, especially the heating of the middle-phase column is more serious, and it is usually cooled by water.

The connection seat adopts the practice of water cooling of ordinary carbon steel, although it can achieve the purpose of cooling, but it cannot reduce the power loss of the transformer. Therefore, this method is not desirable.

SAF Type & Service

HANI Metallurgy is a SAF China manufacturer with rich experience in production and export.

We can design and manufacture furnaces with the appropriate power according to the specific needs of our customers.

Types of furnaces

SAF is mainly used for reduction of raw materials such as smelting ores, carbonaceous reducing agents and solvents.

It mainly produces ferrosilicon, ferromanganese, ferrochrome, ferrotungsten, silicomanganese alloy and other ferroalloys.

The following models are in high demand by users.

16500KVA industrial silicon, 12500KVA silicon-aluminum furnace, 16500KVA silicomanganese furnace, 16500KVA ferro-nickel furnace, 33000KVA ferrosilicon furnace, 33000KVA ferrosilicon furnace, 25500KVA ferrochrome furnace, 8000KVA industrial silicon furnace

and other customized furnaces according to customer requirements.

Services

HANI Metallurgy can provide “turnkey” services for technical solutions, production line design, plant layout, equipment manufacturing, installation and commissioning of relevant projects.

We can also design, manufacture, modify and upgrade your existing production equipment according to your requirements.

We will send our engineers to your factory to install and commission the machines and provide reliable after-sales service.

Our machines are easy to operate and maintain.

Production capacity can be adjusted according to customer requirements.

We supply complete plants as well as individual plants such as furnace shells, furnace covers, furnace liners, short grids, water cooling systems, fume extraction systems, dust removal systems, electrode shells, electrode press and lift systems, loading and unloading systems, grippers, burn-throughs, hydraulic systems, transformers for mineral-heating furnaces and various auxiliary equipment and accessories.