Description

Electric arc furnace shell is a metal shell welded by steel plates of different thicknesses.

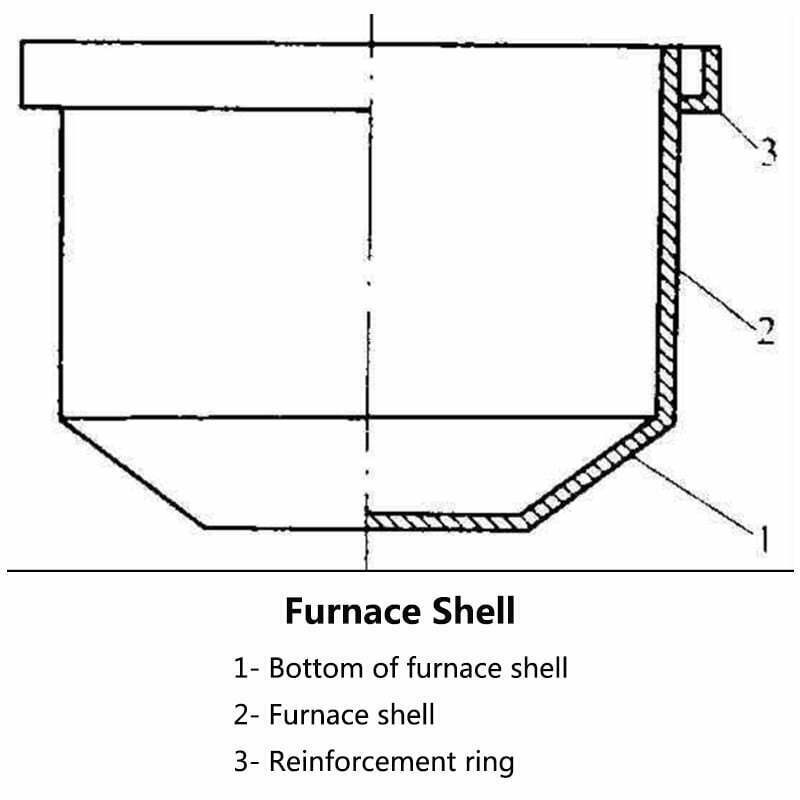

The furnace shell structure is shown in Figure 2.

The thickness of the steel plate used is related to the inner diameter of the furnace shell.

According to experience, it’s about 1/200 of the inner diameter of the furnace shell.

It’s mainly composed of furnace body, furnace bottom and reinforcement ring.

The furnace body is usually made into a simple round shape.

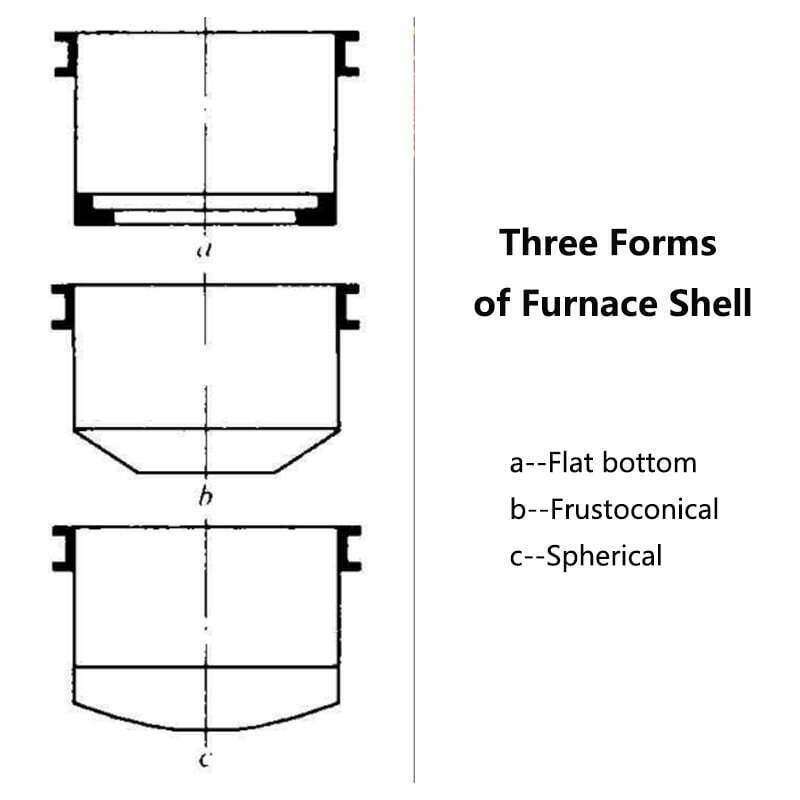

There are three types of electric arc furnace shell bottom: flat bottom, truncated cone bottom and spherical bottom.

The spherical bottom is more reasonable, its rigidity is large, and the refractory material used is the least, but the spherical bottom is difficult to manufacture and the cost is high.

Although the stiffness of the truncated cone bottom is worse than that of the spherical bottom, it is easier to manufacture, so it is still widely used at present.

The flat bottom is the easiest to manufacture, but it has poor rigidity and is easy to deform, and consumes a lot of refractory materials during masonry, so it is rarely used.

(Our HANI Metallurgy produces more furnace shells according to customer needs are spherical and truncated cone).

Advantage of Electric Arc Furnace Shell

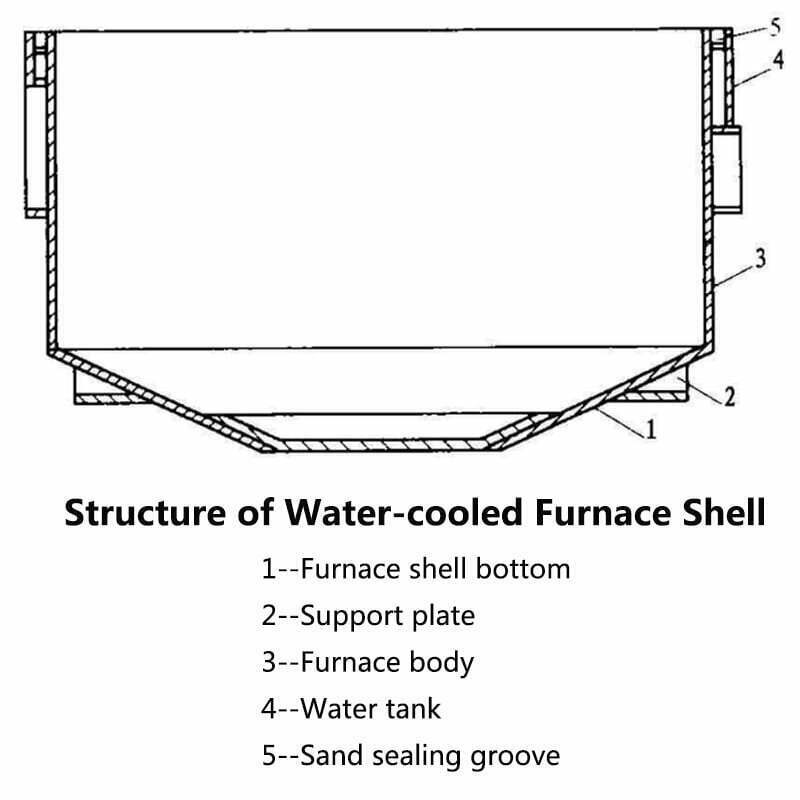

The reinforcement ring on the upper edge of the furnace shell is welded with steel plate or section steel, and the reinforcement ring with water cooling in the middle is used in large and medium-sized electric arc furnaces.

In some electric arc furnaces, the furnace shell above the slag line is cooled by water, so that the furnace shell becomes an interlayer water cooling shell.

There is a sand sealing groove on the upper part of the reinforcement ring, so that the furnace cover ring is inserted into the groove and filled with magnesia to seal it.

In order to prevent the furnace cover from sliding off when the furnace is tilted, a blocking bolt or baffle is installed on the furnace shell.

In order to observe the conditions in the furnace and operate such as slag removal, oxygen blowing, sampling, temperature measurement, material feeding, etc.,

there is a furnace door on the furnace body, usually only one, which is opposite to the tapping port.

There are many evenly distributed ventilation holes drilled on the steel plate of the electric arc furnace shell to remove the moisture during baking.

In addition to bearing the full weight of the furnace lining and charge, the furnace shell also bears the strong impact force generated during top charging, as well as the thermal stress caused by the thermal expansion of the furnace lining.

At the same time, a spare furnace shells should be prepared, and it can be replaced in a hot state to improve the operation rate of the furnace.

Typically, the temperature in most areas of the EAF shell is around 200°C.

The thickness of the furnace shell steel plate is about 1/200 of the furnace shell diameter. Generally 12~30mm.

When the furnace lining is partially burned, the furnace shells temperature is higher. Therefore, the electric arc furnace shell is required to have sufficient mechanical strength and rigidity.

Therefore, when choosing a furnace shell, be sure to choose a manufacturer with a reputation and good after-sales service.

Electric Arc Furnace Application Range

HANI Metallurgy is an experienced Chinese manufacturer of electric arc furnaces.

Committed to providing high quality EAF and its auxiliary equipment/spare parts.

Available Range

1 ton, 6 tons, 15 tons, 40 tons, 70 tons, 100 tons, 120 tons, 200 tons, 250 tons, 300 tons, 420 tons,

And various high-power / ultra-high-power electric arc furnaces according to customer requirements.

Smelting Range

The electric arc furnace can not only smelt high-quality steel with low phosphorus, sulfur and oxygen content, but also can be alloyed with a variety of elements (including easily oxidized elements such as lead, boron, vanadium, titanium, and rare earths) to produce various high-quality steels and alloy steels.

Such as ball bearing steel, stainless acid-resistant steel, tool steel, electrical steel, heat-resistant steel, magnetic materials and special alloys.

Service

For the melting of alloy steel, stainless steel, carbon structural steel and high-quality carbon steel, HANI Metallurgy can provide “turnkey” service of production line design, workshop layout, equipment manufacturing, installation and commissioning according to customer requirements.

It can also design, manufacture, transform and upgrade its existing smelting production equipment according to user requirements.