Description

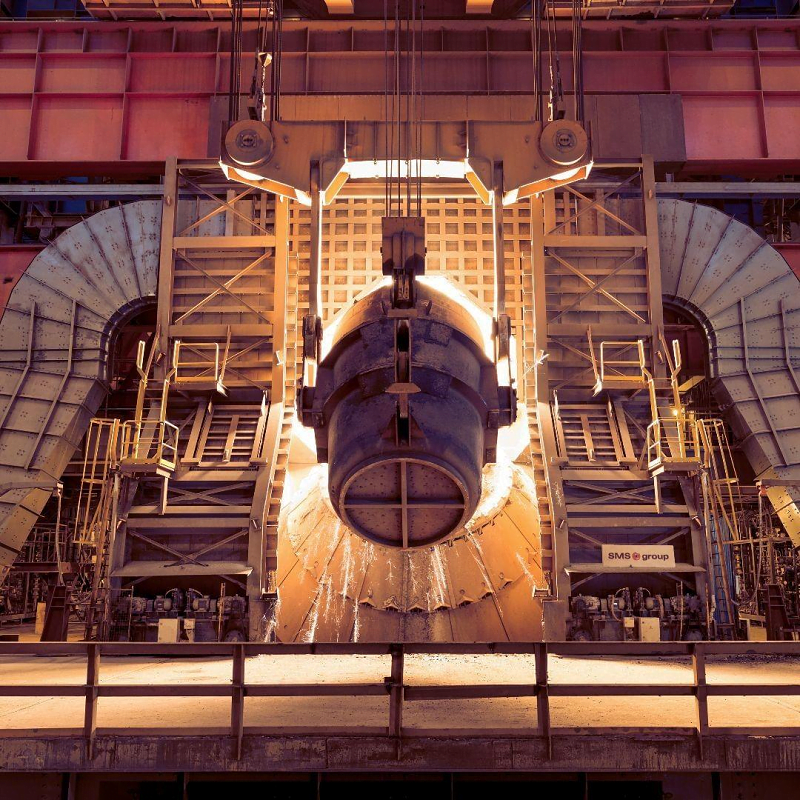

The main equipment of submerged arc furnace includes submerged arc furnace body, electrode system, feeding system, water cooling system, tapping system, safety protection system, etc.

In the submerged arc furnace, due to the high temperature released by the arc, the charge is melted and the reduction reaction is carried out to generate the finished product.

The furnace body is the reaction place provided for the smelting reaction zone of the submerged arc furnace, which is used to store the charge involved in the smelting reaction, and is also the container of the metal molten pool.

Characteristic

The furnace body is made of furnace shell (generally Q235 steel) and refractory materials.

The furnace shell sits on the bottom I-beam, and the bottom I-beam sits on the foundation of the electric furnace.

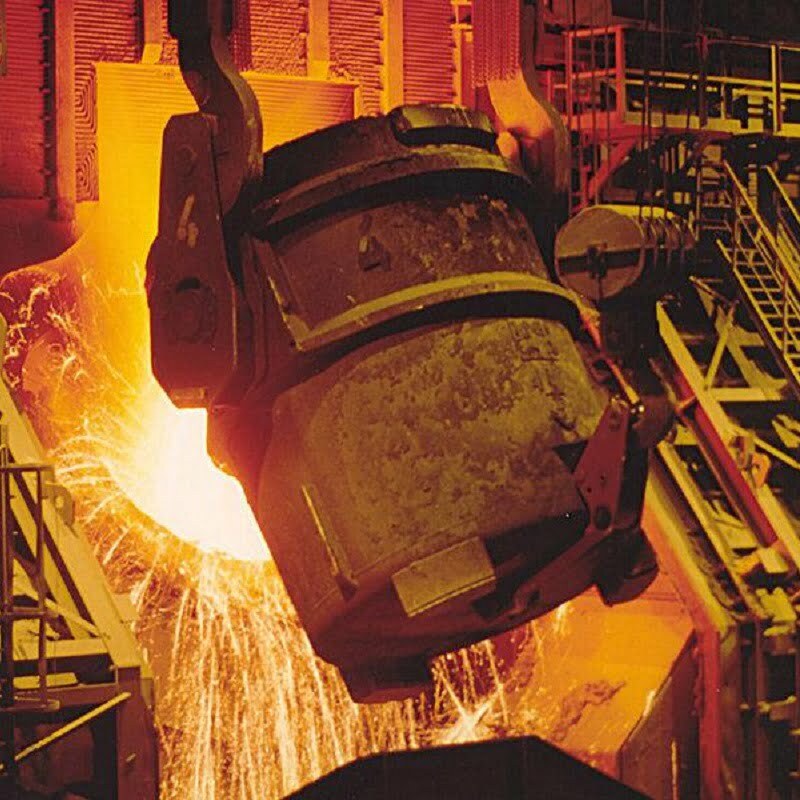

The electrodes transmit a large current into the furnace, and the electric energy is converted into heat energy through the resistance of the charge between the electrodes and the arc generated at the end of the electrode or only the arc generated at the end of the electrode.

In submerged arc operation, a high temperature reaction zone is formed due to the concentration of heat from the arc, which is commonly referred to as the crucible zone in submerged arc operation.

The temperature in the crucible area is as high as 2000~2500T, the inner temperature of the crucible wall soaked with coke is about 1900℃, and the outer layer is about 1700℃.

The area far from the electrode is easy to form a dead material area;

In open arc operation, however, the arc heat generated at the ends of the electrodes provides heat throughout the reaction zone.

The furnace body can be divided into circular furnace and rectangular furnace according to the distribution of electrodes in the furnace and the shape of the furnace body.

The appropriate furnace body and furnace shell can be selected according to the needs for matching.

SAF Type & Service

HANI Metallurgy is a SAF China manufacturer with rich experience in production and export.

We can design and manufacture furnaces with the appropriate power according to the specific needs of our customers.

Types of Furnaces

SAF is mainly used for reduction of raw materials such as smelting ores, carbonaceous reducing agents and solvents.

It mainly produces ferrosilicon, ferromanganese, ferrochrome, ferrotungsten, silicomanganese alloy and other ferroalloys.

The following models are in high demand by users.

16500KVA industrial silicon,

12500KVA silicon-aluminum furnace,

16500KVA silicomanganese furnace,

16500KVA ferro-nickel furnace,

33000KVA ferrosilicon furnace,

33000KVA ferrosilicon furnace,

25500KVA ferrochrome furnace,

8000KVA industrial silicon furnace

and other customized furnaces according to customer requirements.

Services

HANI Metallurgy can provide “turnkey” services for technical solutions, production line design, plant layout, equipment manufacturing, installation and commissioning of relevant projects.

We can also design, manufacture, modify and upgrade your existing production equipment according to your requirements.

We will send our engineers to your factory to install and commission the machines and provide reliable after-sales service.

Our machines are easy to operate and maintain.

Production capacity can be adjusted according to customer requirements.

We supply complete plants as well as individual plants such as furnace shells, furnace covers, furnace liners, short grids, water cooling systems, fume extraction systems, dust removal systems, electrode shells, electrode press and lift systems, loading and unloading systems, grippers, burn-throughs, hydraulic systems, transformers for mineral-heating furnaces and various auxiliary equipment and accessories.