Description

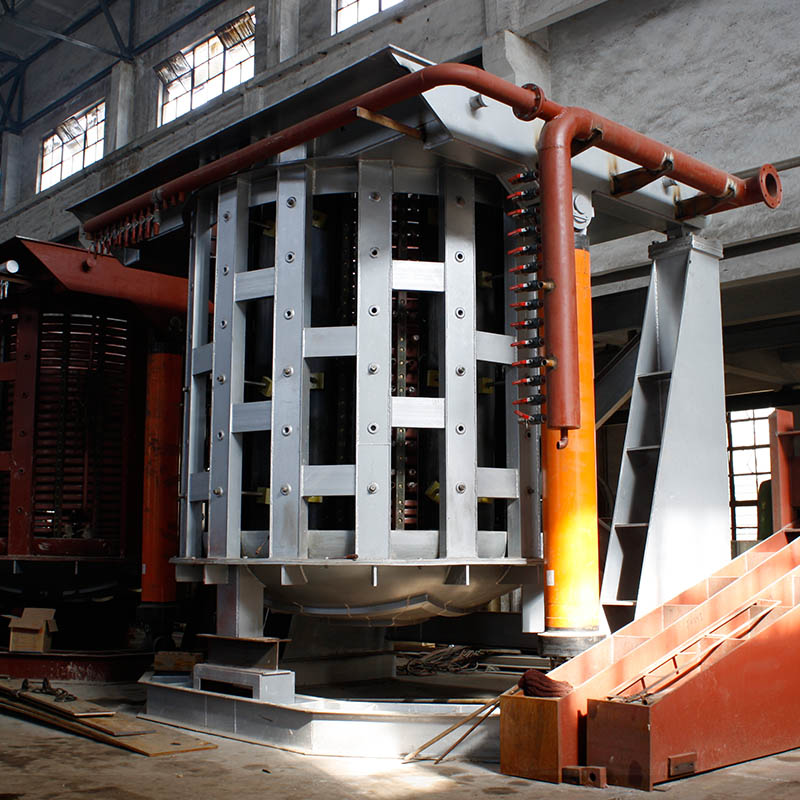

Magnetic Yoke for an Induction Crucible Furnace

Magnetic yoke for an induction crucible furnace usually refers to the soft magnetic material that does not produce a magnetic field (magnetic line of force) and only transmits the magnetic line of force in the magnetic circuit. The yoke is generally made of soft iron, A3 steel, and soft magnetic alloy with high permeability. On some special occasions, the yoke is also made of ferrite material.

The magnetic yoke is a yoke made of silicon steel sheets. It is evenly and symmetrically divided around the induction coil. Its function is to restrict the outward diffusion of magnetic leakage of the induction coil and improve the efficiency of induction heating. In addition, as a magnetic shield, it can reduce the heating of metal components such as the furnace frame and also reinforce the inductor.

Equipment Composition

The magnetic yoke of medium frequency furnaces generally adopts high-quality high-permeability cold-rolled oriented silicon steel sheets of WISCO. In order to ensure the stacking quality of silicon steel column iron core, special positioning assembly welding and silicon steel sheet stacking platform are made. The lamination assembly adopts an arc stacking process. This silicon steel column has a good structural compaction effect and less magnetic leakage. It is closer to the inductor coil of the medium frequency furnace, improves the magnetic flux direction, eliminates the local magnetic flux saturation of the iron core at the joint, reduces the no-load loss and no-load current of the iron core, makes full use of the magnetic conduction area of the silicon steel sheet, enhances the magnetic conduction capacity, and reduces the possibility of local heating of the medium frequency smelting furnace.

The contact part between the stainless steel plate on the yoke cover of the medium frequency furnace and the silicon steel sheet is separated by a high-grade gold cloud motherboard, the outside is clamped and welded with stainless steel, and a copper 2-in-2-out heat dissipation pipe is clamped. The yoke is cooled by water to avoid deformation caused by temperature rise and covers 65% of the surface of the induction coil. The magnetic lines of force are effectively gathered in the molten pool of the smelting furnace to prevent the furnace shell of the medium frequency furnace from heating and improve the system efficiency; Stable performance and reliable support for the inductor coil.

Parameters

The magnetic yoke is made of high permeability cold-rolled silicon steel sheet of WISCO. The thickness of silicon steel sheet is 0.30mm. The yoke adopts a profiling structure, and the radian of its inner arc surface is the same as that of the outer circle of the induction coil, so that the yoke can be close to the outside of the induction coil, with a coverage rate of about 60%, so as to restrict the outward magnetic field of the coil to the greatest extent and reduce the magnetic resistance of the outer magnetic circuit. Magnetic flux leakage is about 15%; It will not affect the operators due to the leakage of the furnace body.

The magnetic yoke is clamped by stainless steel plates and stainless steel clamps on both sides and fixed by welding. Red copper cooling water pipe is welded on the stainless steel plate on both sides to cool the yoke. The cooling water pipe can withstand 0.45MPa water pressure and there is no leakage within 15min. After the final assembly of the yoke, the curvature shall not be greater than 4mm, and the deviation between the theoretical centerline and the actual centerline shall not be greater than 3mm.

Advantages

A profiling magnetic yoke is built into the intermediate frequency electric furnace body to reduce local heating of the intermediate frequency electric furnace body. The shielding of the magnetic yoke can reduce magnetic flux leakage, prevent the furnace body from heating, and improve efficiency.

At the same time, the magnetic yoke plays the role of supporting and fixing the induction coil, so that the furnace body can achieve high strength and low noise.

The yoke is a crescent-shaped yoke made of cold-rolled silicon steel sheet and stainless steel splint. The joint surface of the iron core and the coil is an arc surface, and the pressing place is a surface instead of a line in the past. This kind of structural compression effect is good with less magnetic flux leakage.

After the silicon steel sheets are stacked, they are tightened with a special splint instead of a special through-core screw. This structure can make full use of the magnetic conductive area of the silicon steel sheet and reduce the possibility of local heating of the intermediate frequency electric furnace body.

Customized Magnetic Yoke for an Induction Crucible Furnace

We can design and manufacture the magnetic yoke of a medium-frequency furnace according to the client’s required capacity, working hours, power supply, raw materials, and other related parameters. It can also be matched for users who already have an induction melting furnace.

The Importance of the Magnetic Yoke for An Induction Crucible Furnace

The medium-frequency furnace has a built-in profiling yoke. The yoke shield can reduce magnetic leakage, prevent the furnace from heating and improve its efficiency. At the same time, the magnetic yoke supports and fixes the induction coil, so that the furnace body has high strength and low noise.

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different need

Production capacity can be adjusted according to customer requirements

Low energy consumption