What is continuous casting process? The continuous casting machine process is a revolutionary technology that has transformed metal manufacturing. It continuously pours molten metal into a water-cooled mold, extracting heat from the metal and solidifying it into the desired shape.

The process eliminates the need for multiple casting steps, increasing efficiency and reducing production time. In this article, we will explore the continuous caster and process in detail and discuss its significance in various industries.

What Is Continuous Casting Process?

Continuous casting is an efficient and economical method used in manufacturing to produce long, uniform metal shapes. Continuous casting offers many advantages over traditional casting methods, such as improved product quality, shorter production time, and improved operational efficiency.

a) The first step in the casting process of continuous casting machines is the preparation of the casting mold.

The mold consists of water-cooled copper plates, called mold walls, which are responsible for rapidly cooling the molten metal. The mold is designed to have the desired shape and size of the final product.

Maintaining the temperature and cooling rate of the mold is important to ensure proper solidification of the metal.

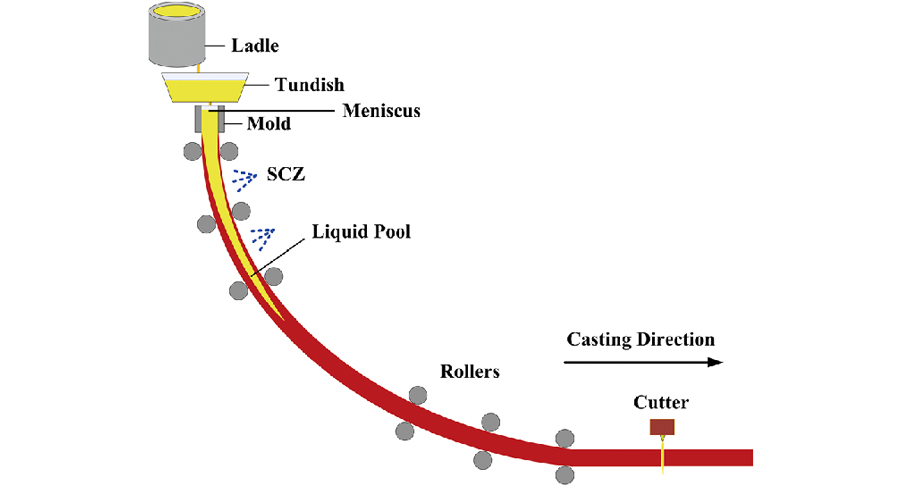

b) The molten metal is thereafter poured into the mold through a tundish which acts as a liquid reservoir.

The tundish ensures a continuous flow of molten metal into the mold, enabling continuous casting.

Molten metal enters the mold at a controlled rate, ensuring that the solidification process occurs evenly.

c) When the molten metal enters the mold, the liquid metal contacts the water-cooled mold wall and cools rapidly causing it to solidify. The solidification process begins at the walls of the mold and progresses inward toward the center of the metal. This controlled solidification produces a uniform grain structure that improves the mechanical properties of the final product.

Once solidified, the metal leaves the mold as a continuous wire, which is called a “blank.” The billet is then directed through a series of rollers and water sprays, which further cool the metal and shape it. These rollers and sprays help maintain the desired dimensions and surface quality of the final product.

Advantages Of Continuous Casting Machine

Continuous casters offer several advantages over traditional casting methods.

First, it can produce long, continuous shapes without having to weld or connect multiple parts together.

This improves product quality and reduces the risk of defects. Additionally, CCM reduces the need for subsequent machining operations, thereby saving time and costs during the production process.

Additionally, continuous casting improves operational efficiency by reducing scrap and material waste.

The continuity of the process ensures a stable production flow, minimizing downtime and increasing productivity. It also allows for better control of production parameters, resulting in consistent and predictable product quality.

Continuous casting is used in a variety of industries, including steel, aluminum, copper and other non-ferrous metals. It is widely used in the production of rods, tubes, rods and other long metal profiles. The process has revolutionized metal manufacturing, enabling high-quality products to be produced faster and more cost-effectively.

In summary, the continuous casting process is an efficient and advantageous method in manufacturing. It provides many benefits such as improved product quality, reduced production time and improved operational efficiency. Continuous casting revolutionized metal manufacturing and continues to play a vital role in various fields.