Description

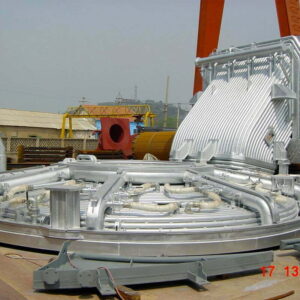

Induction Furnace Coil

The induction furnace coil is the core of the induction furnace, also known as the induction coil, which plays an important role in the medium-frequency furnace body. The principle and importance of induction coil of medium frequency furnace are as follows:

The induction coil of medium frequency furnaces, medium frequency electric furnaces and medium frequency smelting furnaces can produce a strong magnetic field under the action of the current. This induced magnetic field makes the metal in the furnace produce an eddy current, and the eddy current flowing in the metal will produce heat. This is the basic principle of metal heating. That is the key to the conversion of electric energy into heat energy of induction coil, so the design of induction coil of medium frequency furnace is important.

The induction coil of medium frequency electric furnace and medium frequency smelting furnace is a better scheme determined by the calculation of computer professional software based on the actual use of medium frequency electric furnace and the principle of the electromagnetic field. The error between the design power of the induction coil and the actual operating power is no more than 5%. The insulation of induction furnace coil, especially the inter-turn insulation, is guaranteed by advanced insulation treatment, The special bakelite clamping technology can effectively reduce the axial vibration of the coil.

The inner wall of the induction ring is coated with imported high temperature resistant insulating materials and equipped with a furnace leakage alarm system, which can effectively prevent the medium frequency electric furnace from penetrating the furnace. Optional lining ejection mechanism, which can quickly remove the damaged lining and facilitate rapid furnace building. The coil of the medium frequency furnace is the heart of medium frequency furnace, medium frequency electric furnace and medium frequency smelting furnace. The induction coil generates a strong magnetic field under the action of current, which makes the metal in the furnace generate eddy current and heat.

Equipment Composition

The induction furnace coil of the medium frequency smelting furnace produced by our company is wound with a high-quality copper tube. In order to ensure the reliability of the induction furnace coil, T2 high-quality cold extruded copper pipe with a purity of 99.9% is used as the copper pipe. This kind of copper pipe has good density and uniform wall thickness. The influence of the inherent length of the copper pipe is considered in the design of the induction coil, and the welding part of the copper pipe is combined with the power supply and water diversion part, so that there is no weld in each group of induction furnace coil.

The upper and lower parts of the induction coil are equipped with stainless steel water-cooling rings, which aims to make the furnace lining material heat evenly in the axial direction and prolong the service life of the furnace lining.

The induction coil is fixed by a series of bolts and insulating braces welded on the outer circumference. After the coil is fixed, the turn spacing error shall not be greater than 2mm.

Stainless steel or copper water-cooling rings are set at the upper and lower parts of the induction coil to gradually form a gradient when the furnace lining material is heated in the axial direction, so as to prolong the service life of the furnace lining.

The induction coil is also provided with a short-circuit ring to lock the magnetic field and prevent the furnace body from heating.

Parameters

| Furnace Body Model |

Furnace body diameter(mm)

|

Inner Diameter of Induction Furnace Coil(mm)

|

Copper pipe size(mm)

|

|

0.1T

|

Φ630

|

Φ300

|

25×30×2

|

|

0.25T

|

Φ730

|

Φ450

|

25×30×2

|

|

0.35T

|

Φ730

|

Φ580

|

25×40×3

|

|

0.5T

|

Φ1100

|

Φ580

|

25×40×3

|

|

0.75T

|

Φ1100

|

Φ580

|

25×40×3

|

|

1T

|

Φ1180

|

Φ720

|

25×40×3

|

|

1.5T

|

Φ1250

|

Φ760

|

25×40×3

|

|

2T

|

Φ1350

|

Φ860

|

30×50×4

|

|

3T

|

Φ1400

|

φ980

|

30×50×4

|

Features

1. Long Service Life

Induction heating equipment will not generate heat because of the induction coil itself, with long service life, no maintenance and replacement cost; The heating part adopts a ring cable structure, and the cable itself will not produce

It generates heat and can withstand high temperatures above 500 ℃, with a service life of up to 10 years. No maintenance is required, and there is basically no maintenance cost in the later stage.

2. Safe and Reliable

Heat is fully utilized without loss. The heat is concentrated inside the heating body, and the surface temperature of the induction coil is slightly higher than the room temperature. It can be safely touched without high-temperature protection, which is safe and reliable.

3. High Efficiency and Energy Saving

The medium frequency diathermy furnace adopts the internal heating mode, which generates heat by direct electromagnetic induction of some parts in the heating body. The thermal start-up is very fast. The average preheating time is more than 60% shorter than that of the resistance coil heating mode, and the thermal efficiency is more than 90%. Under the same conditions, it saves 30 & mdash; electricity than the resistance coil heating by 70%, greatly improving the production efficiency.

4. Accurate Temperature Control

The coil itself does not generate heat, has a small thermal block, low thermal inertia, consistent temperature, real-time and accurate temperature control, and significantly improves product quality and high production efficiency.

5. Good Insulation

The induction coil of the induction furnace is made of customized special high-temperature and high-voltage special cable, with good insulation performance, no direct contact with the outer wall of the tank, no leakage, short-circuit fault, and safety.

Customized Induction Furnace Coil

We can design and manufacture the induction coil according to the client’s required capacity, working hours, power supply, raw materials, and other related parameters. It can also be matched for users who already have an induction melting furnace.

Custome Range

The common specifications of induction furnace heating coil are:

10×10×2mm; 12×14×2mm; 14×16×2mm; 16×18×2mm; 18×20×2mm;

20×10×2mm; 22×18×2mm; 24×15×2mm; 25×20×2mm; 26×20×2mm.

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different need

Production capacity can be adjusted according to customer requirements

Low energy consumption