Description

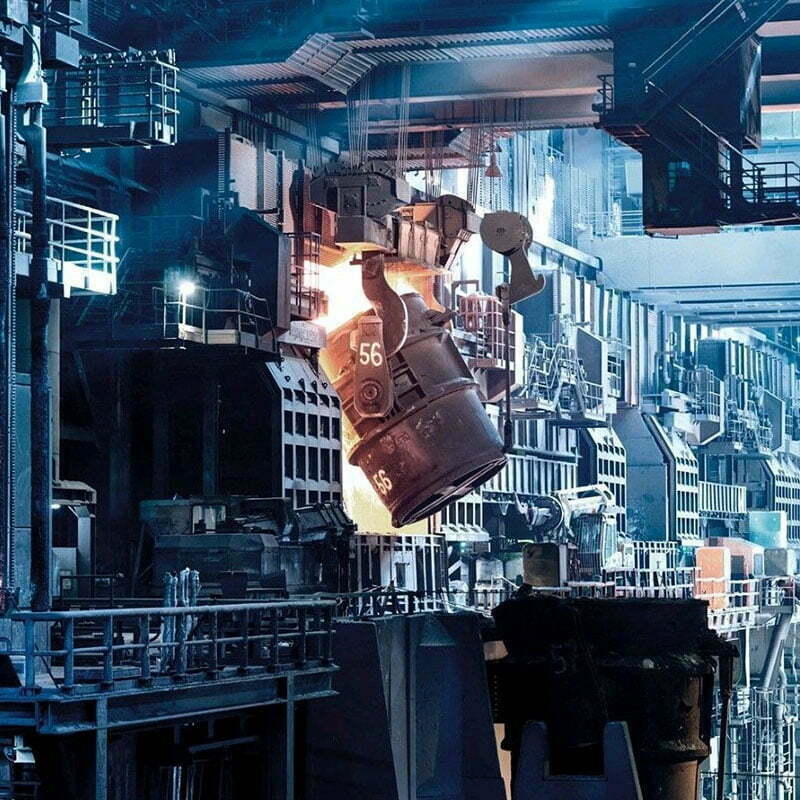

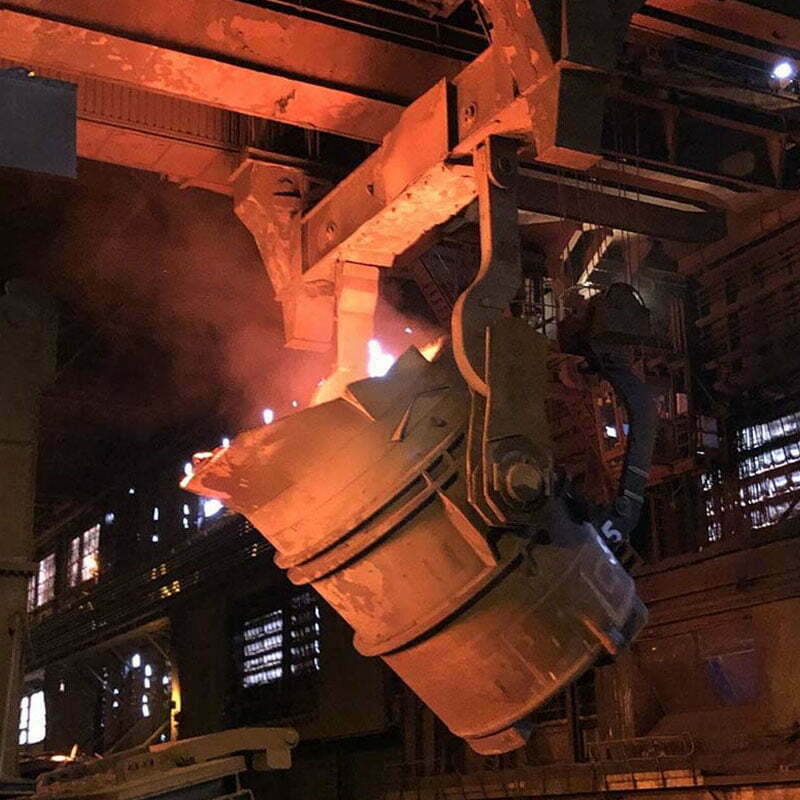

Ladle for Ladle Refining Furnace

The ladle for ladle refining furnace is an important piece of equipment for continuous casting. It is a container for carrying and holding molten steel from tapping to pouring. It is also commonly known as large tank, steel tank, ladle and so on.

Equipment composition

The utility model is composed of a can body, an inner lining, a water inlet opening and closing device, a breathable brick and other parts. From outside to inside, the inner lining is divided into three layers: thermal insulation layer, middle layer and working layer; From top to bottom, the working layer consists of several parts, such as cladding edge, slag line, cladding wall and cladding bottom, and the cladding bottom includes refractory materials for cladding bottom, nozzle device, seat brick and breathable brick.

Function

The function of the ladle is mainly to receive the molten steel and some slag flowing from the tapping valve of the primary molten steel furnace (converter or electric furnace), and carry out partial deoxidation and alloying operation, which can make the molten steel calm for a period of time, so as to adjust the molten steel temperature, uniform the composition and float the non-metallic inclusions in the molten steel. At the same time, open and close the molten steel flow in the pouring process, control the molten steel flow and make the pouring smooth. In recent years, in order to further improve the quality of steel, ladle argon blowing, ladle vacuum treatment and other technologies have been adopted. It is gradually evolving into important equipment for secondary refining unit, and plays an important role in secondary refining and continuous casting.

Design

The ladle can be “lip dumping” design, “teapot mouth” design, “lip shaft design” or “bottom dumping” design:

For the inverted lip design, the ladle is tilted and the molten metal is poured out of the ladle like molten steel.

The teapot spout is designed like a teapot. Take the liquid from the bottom of the ladle and pour it out through the lip. Any impurities in the molten metal will form at the top of the metal, so by removing the metal from the bottom of the ladle, the impurities will not be poured into the mold. The same idea is behind the bottom pouring process.

The pivot point of the container of the lip shaft ladle is as close as possible to the tip of the pouring port. Therefore, when the ladle rotates, the actual pouring point has little movement. Lip casting is usually used in molten metal casting systems that need to be as automated as possible, and the operator can remotely control the casting operation.

For the bottom ladle, insert the plug rod into the tap hole at the bottom of the ladle. To pour the metal, raise the plug vertically to allow the metal to flow out of the bottom of the ladle. To stop dumping, reinsert the plug rod into the drain hole. Large ladles in the steelmaking industry may use sliding doors under tapholes.

The ladle can be open or covered. The ladle with cover has a (sometimes movable) dome-shaped cover to accommodate radiant heat; They lose heat more slowly than the open-top ladle. The small ladle usually has no cover, although the ceramic blanket can be used instead (if any).

Medium and large ladles suspended from the crane have a hook called a trunnion that secures the ladle to the shaft. In order to tilt the ladle, a gearbox is used, usually a worm gear. The gear mechanism can be operated manually with large wheels, or by the electric motor or pneumatic motor. Electric rotation enables the ladle operator to move to a safe distance and control the rotation of the ladle through the pendant or radio remote control. Dynamic rotation also gives the ladle many rotational speeds, which may be beneficial to the whole casting process. Power rotation obviously also reduces the workload required by the ladle operator and allows a large amount of molten metal to be transported and poured for a long time without causing operator fatigue. In the case of the manual gearbox packaged in steel, the most commonly used type of gearbox is worm gear and worm gear design, because in most practical cases, if properly maintained, it can be regarded as “self-locking”, and there is no need for internal friction braking to adjust the tilting speed of the ladle. Other types of gear systems can also be used, but an additional braking system must be installed to secure the ladle if the operator removes his hand from the handwheel.

The lip shaft ladle can also be tilted by using a hydraulic plunger. The largest ladle has no gears and is usually poured with a special two-winch crane, in which the main winch carries the ladle and the second winch engages with the lug at the bottom of the ladle. Lift the second winch and rotate the ladle on its trunnion.

The ladle is usually designed for special purposes, such as adding alloy to molten metal. The ladle can also insert a multi-hole plug into the base, so inert gas can be introduced into the ladle to enhance the performance of alloying or metal treatment.

Customized Ladle for Ladle Refining Furnace

We can design and manufacture the ladle for ladle refining furnaces according to the client’s required capacity, working hours, power supply, raw materials, and other related parameters. It can also be matched for users who already have ladle refining furnaces.

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different need

Production capacity can be adjusted according to customer requirements

Low energy consumption